Add to Cart

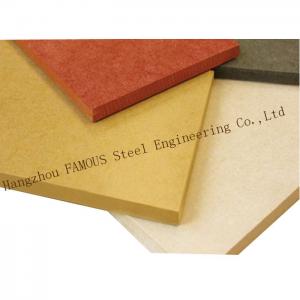

Colored Fiber Cement Board wall Panel

1. Green, low carbon, environmental protection

The main materials of fiber cement board products include: lime

cement, quartz, silicate, imported raw wood pulp fiber, selected

mineral fillers, suspending agents and additives, which are

produced through batch, mixing, curing, autoclave and other

production processes Made; does not contain asbestos materials

harmful to human health;

2. Long span life

Meet the low-cost investment needs of customers; exterior wall

building ventilated curtain wall panels have the following

characteristics: ventilation, heat insulation, moisture expansion

rate of 0.14%, can prevent water vapor from penetrating into the

building structure and walls, reducing the possibility of leakage

To the lowest

3. High impact strength and bending strength

It can resist the impact of high typhoons, and the bending strength

of the external wall panel is 16MPA, which is especially suitable

for the external wall curtain wall panel of various high-end villas

and multi-story high-rise residential buildings in coastal areas.

Typhoon and rainy areas.

4. The interior and exterior wall panels are completely

non-combustible materials

It meets the BS 476 PART 4 standard of the British building

materials fire test. It is suitable for large-scale shopping malls,

schools, cinemas, railway stations, subway platforms and other

crowded places as indoor partition walls.

5. Excellent sound insulation performance

Fiber cement board is suitable for indoor partitions and ceilings

of star-rated hotels, residential bedrooms and public entertainment

places with higher requirements for entertainment and sound

insulation, reducing 30-45dB.

6. Light weight and high strength

It has the advantages of light weight and high strength.

7. Convenient construction

The construction of fiber cement board adopts dry construction,

which is quick and easy. Ordinary woodworking tools can be used,

and the boards are easy to process.

Various surface treatments, such as paint or various adhesives, can

be applied to the surface to stick the panel.

8. Not easy to deform

The materials of fiber cement board are: cement, quartz powder,

natural wood fiber and other minerals. The high-temperature

autoclave promotes the chemical reaction between the calcium in the

cement and the silicon in the quartz powder, thereby forming a new

material crystal "perovskite". The curing reaction process is

completed within 24 hours after molding, so the shape of the sheet

is stable and the deformation coefficient is small.

Details:

Samples

| Product Name | Regular Size | Weight/PC(KGS) | Q'TY of 20'GP |

| Fiber Cement Board | 1220×2440×6 mm | 24 | 900 PCS |

| 1220×2440×8 mm | 32 | 678 PCS | |

| 1220×2440×10 mm | 40 | 540 PCS | |

| 1220×2440×12 mm | 48 | 450 PCS | |

| 1220×2440×15 mm | 60 | 360 PCS | |

| 1220×2440×18 mm | 72 | 300 PCS |

Hangzhou FAMOUS Steel Engineering Co.,Ltd. focus on various structural steel construction and steel-related products supplying. FAMOUS received a lot of foreign projects from project engineering, fabrication, logistic and installation guidance etc. and become more professional in foreign project operation, specially in US-EU standard engineering and project management aspects. It owns advanced professional production equipment for the all automation production line of H type that is most advanced at home, pipe truss structure, box-beam production lines, CNC hydraulic punching posterior cutting C type steel, Z type steel production lines, vertical seam 360-degree whip-stitch roof board of hidden button type, weather board production lines and metal sandwich panel production lines, etc.