Add to Cart

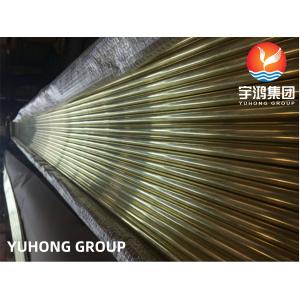

UNS C68700 / CuZn20Al2 / CW307G Aluminum Brass Copper Alloy Tube Heat Exchanger Tube

UNS C68700 is a copper-zinc alloy known as Aluminum Brass. It is commonly used in marine environments due to its excellent corrosion resistance and high strength. However, it does not have exact equivalent grade since different countries and standards may use different numbering systems.

The advantages of ASTM B111 C68700 copper alloy tube

3. Good formability and weldability: These tubes can be easily formed into different shapes and sizes, making them versatile for various fabrication processes. Additionally, they have good weldability, enabling easy joining with other components or fittings.

| COUNTRY | STANDARD | NAME |

| ASTM | ASTM B111 | Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stock |

| GB/T | GB/T8890 | Seamless Copper Alloy Heat Exchanger Tubes |

| BS | BS 2871 CZ110 | Copper and Copper Alloys Tubes |

| JIS | JIS H3300 | Copper and Copper Alloy-Seamless Pipes and Tubes |

| DIN | DIN1785 | Wrought Copper and Copper Alloy Tubes for Condensers and Heat Exchangers |

ASTM B111 C68700 Copper Alloy Mechanical Properties

| Copper or Copper Alloy UNS No. | Temper Designation | Annealing temperature, °C | Tensile Strength, minYield Strength, min | Yield Strength, min | HV | |||

| Code | Surface | Ksi | Mpa | Ksi | Mpa | |||

| C68700 | O61 | Annealed | above 650 | 50 | 345 | 18 | 125 | 150 |

| Chemical Compositions% | |||||||||||||

UNS No. | CopperA | Tin | Al | Nickel, incl Cobalt | Lead, max | Iron | Zinc | Mn. | Arsenic | Antimony | Phosphorus | Chro | Others |

| C10200 | 99.95 min | - | - | - | - | - | - | - | - | - | - | - | - |

| C12000 | 99.90 min | - | - | - | - | - | - | - | - | - | 0.004-0.012 | - | - |

| C12200 | 99.9 min | - | - | - | - | - | - | - | - | - | 0.015-0.040 | - | - |

| C14200 | 99.40 min | - | - | - | - | - | - | - | 0.15-0.50 | - | 0.015-0.040 | - | - |

| C19200 | 98.7 min | - | - | - | - | 0.8-1.2 | - | - | 0.15-0.50 | - | 0.01-0.04 | - | - |

| C23000 | 84.0-86.0 | - | - | - | 0.05 | 0.05 max | remalnder | - | - | - | - | - | - |

| C28000 | 59.0-63.0 | - | - | - | 0.30 | 0.07 max | remainder | - | - | - | - | - | - |

| C44300 | 70.0-73.0 | 0.9-1.2 | - | - | 0.07 | 0.06 max | remainder | - | 0.02-0.06 | - | - | - | - |

| C44400 | 70.0-73.0 | 0.9-1.2 | - | - | 0.07 | 0.06 max | remainder | - | - | 0.02-0.10 | - | - | - |

| C44500 | 70.0-73.0 | 0.9-1.2 | - | - | 0.07 | 0.06 max | remainder | - | - | - | 0.02-0.10 | - | - |

| C60800 | remainder | - | 5.0-6.5 | - | 0.10 | 0.10 max | - | - | 0.02-0.35 | - | - | - | - |

| C68700 | 76.0-79.0 | - | 1.8-2.5 | - | 0.07 | 0.06 max | remainder | - | 0.02-0.10 | - | - | - | - |

| C70400 | remainder | - | 4.8-6.2 | 0.05 | 1.3-1.7 | 1.0max | 0.30-0.8 | - | - | - | - | - | |

| C70600 | remainder | - | 9.0-11.0 | 0.05B | 1.0-1.8 | 1.0maxB | 1.0max | - | - | B | - | B | |

| C71000 | remainder | - | 19.0-23.0 | 0.05B | 0.50-1.0 | 1.0maxB | 1.0max | - | - | B | - | B | |

| C71500 | remainder | - | 29.0-33.0 | 0.05B | 0.40-1.0 | 1.0maxB | 1.0max | - | - | B | - | B | |

| C71640 | remainder | - | 29.0-32.0 | 0.05B | 1.7-2.3 | 1.0maxB | 1.5-2.5 | - | - | B | - | B | |

| C72200 | remainder | - | 15.0-18.0 | 0.05B | 0.50-1.0 | 1.0maxB | 1.0max | - | - | B | 0.30 -0.70 | B | |

Application

Heat Exchangers

Desalination Plants

Power Generation

Shipbuilding

Oil and Gas Industry

HVAC Systems

Water Treatment

Automotive Industry