Add to Cart

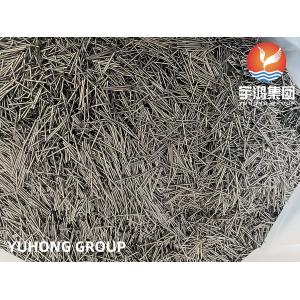

Capillary Tubes For Refridgerators Condeser TP304 Stainless Steel Seamless Tube

The refrigeration engineer who designed the system specifies the internal diameter and the length of the capillary tube to be used - that's it. The flow rate through the cap tube will be fixed and is a function of the tube length, diameter, and operating pressure at which the liquid refrigerant is being delivered.

In the field, capillary tubing comes in a pack of given diameter tubing size. The technician cuts off the desired length to carefully solder in place if field replacement is needed.

The Benefits of Stainless Steel Capillary Tubing

High precision, seamless stainless steel capillary tubing is used

in a wide range of instrumentation measurement applications. Based

on heavy wall, small diameter construction (typically 1/8” or

less), this tubing is used in critical applications from nuclear

reactors to resistojets in aerospace.

Because high quality seamless capillary tube is made from a single

homogeneous piece of steel with a continuous, uninterrupted grain

structure, it is more suitable for applications which require

consistent material throughout the tubing. Welds and mechanical

fittings permit discontinuities that can encourage crevice

corrosion and mechanical failure.

High quality stainless steel allows for the formation of a passive

protective layer at the surface in the presence of oxygen. Poor

heat treatment and welding can affect this layer by changing the

critical chemical composition in the Heat Affected Area (HAZ) due

to the different alloying elements having differing melting points.

Technological advancements in the life sciences market have

resulted in smaller assemblies working under increased operating

pressures. Ultra-small diameter capillary tubing is crucial to the

performance of High Performance and Ultra-Performance Liquid

Chromatography (HPLC and UPLC) equipment. This capillary tubing,

often with outside diameters less than 1/16th inch (1.59 mm) is

used in many critical applications. In addition, seamless capillary

tubing in crucial applications increases necessary sampling

efficiencies.

HPLC is one of the most versatile analysis “tools” in the

laboratory. Even so, there are common ‘hurdles’ many

chromatographers face, such as; band broadening, poor resolution,

and undesirable peak shapes. When selecting tubing for HPLC

applications it is crucial to consider:

Many of these applications require smooth-bore capillaries to limit

Newtonian flow through the sample loop to ensure in a better sample

read.

Certain specialized manufacturing techniques allow for critical

product cleanliness required in these applications. Impurities,

such as oil, grease and other foreign material leftover from the

manufacturing process of stainless steel capillary tubing can

result in cross-contamination and inaccurate sample readings.

Conventional tubing typically requires additional cleaning on-site,

prior to installation. To minimize the risk of cross-contamination

and save time, special processes have been developed, during which

tubing is subjected to high pressure and temperature cleaning

immediately following the manufacturing process to remove residual

impurities. This ensures tubing with fewer impurities and allows

for sample integrity, providing repeatably consistent results.

Stainless Steel Capillary Tube Chemical Composition

The below table shows the chemical composition of the used for

Stainless Steel Capillary Tube:

| STAINLESS STEEL CAPILLARY TUBE GRADES | UNS | C | Mn | P | S | Si | Cr | Ni | Mo | Ti | Nb | N |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-11.0 | ||||

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0-20.0 | 8.0-13.0 | ||||

| TP316 | S3160 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 11.0-14.0 | 2.0-3.0 | |||

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

Stainless Steel Capillary Tube Mechanical Properties

| Material | Heat | Temperure | Tensile Strength | Yield Strength | Elongation %, Min |

| Treatment | Min. | Ksi (MPa), Min. | Ksi (MPa), Min. | ||

| º F(º C) | |||||

| TP304 | Solution | 1900 (1040) | 75(515) | 30(205) | 35 |

| TP304L | Solution | 1900 (1040) | 70(485) | 25(170) | 35 |

| TP316 | Solution | 1900(1040) | 75(515) | 30(205) | 35 |

| TP316L | Solution | 1900(1040) | 70(485) | 25(170) | 35 |

Stainless Steel Capillary Tube Equivalent Grades

| GRADE | UNS NO | DIN/WERKSTOFF |

| Stainless Steel Capillary Tube 304 | S30400 | 1.4301 |

| Stainless Steel Capillary Tube 304L | S30403 | 1.4306 |

| Stainless Steel Capillary Tube 316 | S31600 | 1.4436 |

| Stainless Steel Capillary Tube 316L | S31603 | 1.4404 |

High precision capillary tube is used in many Instrumentation systems which include the use of:

Some applications require long lengths of stainless steel coil tubing where joints (welds or fittings) are not acceptable over long runs. However, there are many critical capillary applications which require short lengths of tubing.