Add to Cart

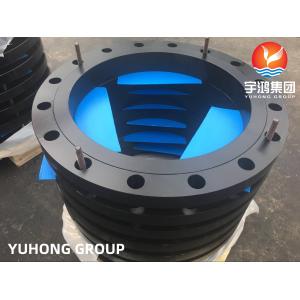

ASTM A105 Carbon Steel Forged Flange BLRF SORF WNRF Black Painted

What is A105 flange?

ASTM A105 is the most generally utilized carbon steel material

grade that used to manufacture forge piping components, for

example, flange and forged fittings of small diameter piping. This

carbon steel material grade is utilized for ambient and

higher-temperature administration in pressure frameworks.

Carbon steel ASTM A105 Flange are made up of carbon steel or mild steel material. The material composition can have carbon, manganese, phosphorus, sulfur and iron in the composition.

YUHONG Group is a leading A105 carbon steel flanges manufacturers of these different carbon steel grades of flanges. Flanges are a type of connections for pipe lines to connect the pipes together.

The specification for carbon steel material made flanges is the Asme Sa105N. There are different types of flanges based on the functionality such as the blind flange, slip on flange and orifice flange.

Chemical Composition:

| Chemical Composition of A105 | |

|---|---|

| Elements | Composition, % |

| Carbon [C] | ≤0.35 |

| Manganese [Mn] | 0.60-1.05 |

| Phosphorus [P] | ≤0.35 |

| Sulfur [S] | ≤0.40 |

| Silicon [Si] | 0.10-0.35 |

| Copper [Cu] | ≤0.40 |

| Nickel [Ni] | ≤0.40 |

| Chromium [Cr] | ≤0.30 |

| Molybdenum [Mo] | ≤0.12 |

| Vanadium [V] | ≤0.08 |

A105 Physical Properties:

| Density (lb / cu. in.) | 0.284 |

| Specific Gravity | 7.9 |

| Thermal Conductivity | 360 |

| Mean Coeff Thermal Expansion | 6.7 |

| Modulus of Elasticity Tension | 30 |

| Specific Heat (Btu/lb/Deg F - [32-212 Deg F]) | 0.107 |

| Melting Point (Deg F) | 2740 |

| Modulus of Elasticity Torsion | 11 |

Mechanical Properties:

| Tensile Strength min. | Yield Strength min. | Elongation min. | Reduction of Area, min. | Hardness | ||

|---|---|---|---|---|---|---|

| MPa | ksi | MPa | ksi | % | % | HBW |

| 485 | 70 | 250 | 36 | 22 | 30 | 137-187 |

ASTM A105 Flange Pressure Rating:

Carbon Steel Flanges pressure rating in psig ( A105 / A350 LF2 / A350 LF3 / A350 LF6) | |||||||

Temperature (F°) | Class 150 | Class 300 | Class 400 | Class 600 | Class 900 | Class 1500 | Class 2500 |

-20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

Heat Treatment:

Heat treatment is not a mandatory requirement of ASTM A105 piping components. However, there are some exceptions: ASME B16.5 flanges Class 400, 900, 1500, 2500; Flanges of special design where the design pressure at the design temperature exceeds the pressure-temperature ratings of Class 300; Flanges of special design where the design pressure or temperature are not known.

The typical heat treatment conducted for A105 forgings includes annealing(A), normalizing(A), normalizing and tempering(NT), quenching and tempering(QT)

Applications:

-Power Plants

-Nuclear Plants

-Oil & Gas Industry

-Refineries

-Ship Building

-Heat Exchangers

-Condensers

-Paper & Pulp

-Marine Applications

-Nuclear Power

-Fossil Fuel Power Plants