Add to Cart

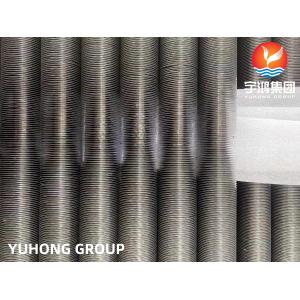

ASME SB163 NO4400 G Type Finned Tube For Economizers and Heat

exchangers

G-Type Finned Tubes are widely used in industries such as petrochemicals, machinery,

metallurgy, rubber, printing and dyeing, pharmaceuticals, food,

electricity, automobiles, drying, etc. They are important heat

transfer components for decomposition furnaces, converter

convection sections, air preheaters, economizers, heat exchangers,

crystal devices, radiators, and heat pipe technology. Especially

steel radiators, they are widely used in industrial and commercial

buildings such as offices, residences, hotels, workshops,

greenhouses, etc. They play a crucial role in heating Outstanding

role.

UNS N04400 nickel copper chemistry has a high-strength single-phase Solid

solution metallurgical structure. Alloy UNS N04400 has higher

corrosion resistance than nickel under reduction conditions and is

more resistant to corrosion than copper under oxidation conditions.

This brand has been widely used in applications that require strong

resistance to corrosive environments such as acid, alkali, and

high-temperature steam. It is almost unaffected by stress corrosion

cracking (SCC) caused by chloride and most freshwater conditions.

Alloy UNS N04400 is a very tough material (measured through impact

testing) that exhibits excellent mechanical properties under

conditions below zero. Even if cooled to the temperature of liquid

hydrogen, it will not undergo ductile brittle transition. On the

other side of the temperature range, alloy UNS N04400 performs well

at temperatures up to 1000 ° F.

Chemical Composition

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Monel 400 | 0.30 max | 2.00 max | 0.50 max | 0.24max | 28.0-34.0 | 2.50 max | 63.00 min | – |

Mechanical Properties

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Monel 400 | 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80,000 , MPa – 550 | Psi – 35,000 , MPa – 240 | 40 % |

Physical Properties

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.8 gm/cm3 | 0.318 lb/in3 |

1. Rubber plants

2. Power plants

3. Petroleum industries

4. Chemical industries

1. Marine engineering.

2. Chemical and hydrocarbon processing equipment.

3. Gasoline and freshwater tanks.

4. Crude petroleum stills.

5. De-aerating heaters.

6. Boiler feed water heaters and other heat exchangers.

7. Valves, pumps, shafts, fittings, and fasteners.

8. Industrial heat exchangers.

9. Chlorinated solvents.

10. Crude oil distillation towers.