Add to Cart

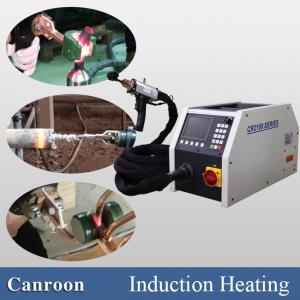

DSP digital high frequency induction brazing machine for stainless steel/copper/aluminum heat treatment

Adopt DSP full digital control system:

multi-circuit protection, with power, frequency, voltage, current display.

DSP digital high frequency induction brazing machine has many advantages over

flame or other brazing methods:

1.Ultra-light and ultra-small handheld transformator,the minimum weight is only 3Kg.

2.High-speed heating is competent for 1s constant temperature control.

3.Fast running mode,heating time can be less than 1s.

4.The handheld transformator connection length is almost unlimited and can exceed 50m.

Brief introduction of DSP digital high frequency induction brazing machinefor

stainless steel/copper/aluminum heat treatment :

Canroon is China leading manufacturer of induction heating machine,

CR2100 series is our widely popular

both in China and oversea countries, digital control, modular

design, LED display panel, HHT, detachable inductor,

soft induction cable, water cooling system.

Inductors are important part of induction heater, so it is precisely designed, manufactured by good quality material,

and tested many times before outgoing, it is detachable, and can be

customized accoridng to your needs:

Parameters of Canroon DSP digital high frequency induction brazing machinefor

stainless steel/copper/aluminum heat treatment:

Model | Rated input voltage & frequency | Rated input power | Rated input current | Output frequency | Cooling water pressure / flow rate | Dimension |

| CR2100-010B | 3-phase /400V (±20%) 50/60Hz | 10KVA | 15A | 10~40KHZ | 4~6 bar ≥12L/min | L: 62.1mm W: 283mm H: 350mm |

| CR2100-015B | 15KVA | 22A | ||||

| CR2100-020B | 20KVA | 30A | ||||

| CR2100-025B | 25KVA | 37A | ||||

| CR2100-030B | 30KVA | 45A | ||||

| CR2100-035B | 35KVA | 53A | ||||

| CR2100-040B | 40KVA | 60A | ||||

| CR2100-050B | 50KVA | 75A | 4~6 bar ≥25L/min | |||

| CR2100-060B | 60KVA | 90A |

Application Ranges for DSP digital high frequency induction brazing machinefor

stainless steel/copper/aluminum heat treatment:

1. alloy cutter welding:such as alloy turning tool, milling cutter, planer, saw blades, reamer, boring knife.

Applications:

Brazing, Annealing, Straightening, Hardening, Bolt Untighten,

Shrink Fitting, Paint/Coating Removal, etc.

see the following detailed application of induction brazing for

copper wire, heat exchanger, rotor coil, rotor bar,

short circuit ring, etc

Following is induction brazing of brass bar with Cu-Ag alloy as the

welding solder to make slip ring for

wide applications.

Product features:

1. High efficient: thermoelectric conversion efficieny: >85%;

2. Enviromental friendly;

3. Intelligent: PID temperature closed-loop control, precise

temperature control;

4. Wide application: for all metal wiredrawing products, including

metal or alloy such as copper, iron, zinc, tin,

aluminum, silver, stainless steel, titanium, nickel.

5. Operation interface: humanized MMI, chinese/ English available;

6. Multiple control interfaces: Heating process can be controlled

accurately by feedback signal sent to the

microcontroller from remote control unit; support 0-10v, 4-20mA

analog signal control; support RS-485

communication;

Production line:

Packaging Details

1. Plywood or wooden case

2. Adhesive wrap to prevent scratches

3. Plastic film to keep the machine together

4. Foam plate and block to prevent shake

5. Other customer's requirements

F&Q

1. Q: what is your MOQ?

A: We would like to do business with every clients. No matter how many sets they order, we would try our

best to meet his or her demands.

2. Q: Is your company a trading firm? or Factory?

A: We are a factory with 12 years experience in China. Welcome to our factory if you like

3. Q: How can we guarantee quality?

Always a pre-production sample before mass production; Always final

Inspection before shipment;