Add to Cart

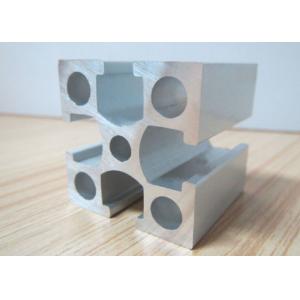

Custom Anodized Industrial Aluminium Profile For Production Line / Pipeline

Anodized Industrial Aluminium Profile For Production Line ,Pipeline Aluminum Profiles

Hentec Industry Co.,Ltd is a professional Company which sales of DIY aluminum products and its' relate products the company mainly take "OEM commercialization" as purpose of product development,the company adhering to customer needs as the core to provide customers with fast and accuratehigh quality products and services. Hentec has own product catalog and a direct sales marketing system,according to the recommendations and requirements of the customers to make products and services planning, and we will do it along.

1. Company with rich manufacturing experience

Hentec Industry Co., Ltd,is one of the leading aluminum

manufacturer in China, with 10 years experience.

2. Production Management

Hentec Industry made complete quality management program and

system, Monitor the process from product development, purchasement,

production, sales and aftersale service.

3. Quality Supervision

Hentec Industry own complete testing equipment from raw material to

finished products. We own the most powerful curtain wall testing

base in China .

Description :

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis,

polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue,grey,

champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling,

bending, welding, CNC etc.

6. Various in styles and sizes:

A) Aluminum alloy bars: 6063,6005,6061,6060, special materials such

as 6082etc.

B) Aluminum profiles:

---General aluminum profiles (various shapes of pipes/tubes,

angles, T or U shapes etc.)

--- Industrial aluminum profiles ( TV frames, Rim for bicycles and

motorcycles, Heat sink profiles, Furniture, Ladder, Guide Rail,

Leisure materials, Shower Room, Solar Module Frame, Motor Shell,

Pipeline Integration etc.)

--- Construction aluminum profiles.

7. Certification: ISO9001,SGS,ROHS,TUV

8. Strong technical development ability, can provide high intensity

and high ductility aluminum profiles, to meet customers' different

requirements.

9. OEM service available, customized design available

| Content | Specification |

| Aluminum Profile | from 20 series to 100 series |

| Fasteners-Nut | t nut, spring nut, slide nut, square nut, hex nut |

| Fasteners-Bolt | t screw, hex socket screw, cross socket screw, cylinder screw |

| Corner Bracket | 1515 bracket, 2020 bracket, 3030 bracket, 4040 bracket, 4545 bracket, 5050 bracket, 2040 bracket, 3060 bracket, 4080 bracket, 50100 bracket |

| Decorative Parts | Slot cover, end caps, hangers, and etc |

| Casters/Support Feet | footmaster casters, adjustable stainless steel feet, and etc |

| Door and Window Accessories | door hange, door handle, slot cover, end caps, and etc |

| Aluminum Profile Frame/Rack/Cabint | AL protection frame for equipment, machine, conveyor, worktable, warehouse, and etc |

Order,payment,terms,shipment

1, Minimum order: 500kg per trial order 1 piece of sample free of

charge provided by approval and kept for future mass production.

2, Sample Lead Time: 25 working days(15 days for making the tool

and 10 days making the samples. Before sending the samples to

customer, samples should pass strict test in our lab. )Production

Lead time: it depends on customers' order quantity ( 30 working

days after deposit).

3, Payment: (Can negotiate with customers, our usual practices are

as follow)

4, Tooling:100% prepaid by T/T.

5, Parts:30% upon order confirmation and balance before delivery by

T/T

Applications:

Mainly used for industrial production , such as automation

equipment , enclosure of the skeleton and the companies according

to their own customized mold machinery and equipment , such as

assembly line conveyor , hoist, dispenser, testing equipment,

shelves , etc., electronic machinery industries and clean room with

a gain majority.

Competitive Advantage:

1. 12 years' experiences of manufacturing, 10 years' exporting

experiences .

2. STRONG R&D: Help customers finalize the design, strong tool

design ability,excellent pressing and surface treament technology.

3. Strict quality management: ISO Administration system.

4. 24 hours on-line communication.Professional, Patient, Flexible.

5. High capacity of manufaturing and wide range of products.

6. Be able to provide secondary fabricating.

7. Small order isaccepted.

8. Be able to provide one-stop supply solution.