Product Details

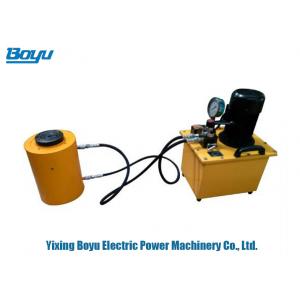

Hollow Plunger Hydraulic Cylinders Double Acting Central Solid

Hydraulic Jack

Product features

- External ring thread, plunger thread and base hole for easy

mounting (for most models)

- The piston parts and the inner side of the guide cap adopt the

copper welding technology, the piston rod surface is plated with

hard chromium, never pull the cylinder, strong wear resistance

- Paint surface for better corrosion resistance

- Movable saddle to protect plunger during operation

- Internal safety valve prevents accidental overload

- All models use quick couplings

- Dust ring reduces pollution and prolongs the service life of

hydraulic cylinder

| Type | TonnageT | Route B-A mm | Body height Amm | Stretching heightBmm | Oil cylinder outer diameter mm | Diameter of piston rod mm | Diameter of oil cylinder mm | Weight kg | Pressure | Recommended pump station |

| DYG50-100 | 50 | 100 | 225 | 325 | 127 | 70 | 100 | 35 | 63mpa | 50T-200T optional 0.55kw 0.75kw 1.5kw 3kw 3kw 4kw 5.5kw |

| DYG50-160 | 160 | 285 | 445 | 39 |

| DYG50-200 | 200 | 325 | 525 | 46 |

| DYG50-300 | 300 | 425 | 725 | 48 |

| DYG50-500 | 500 | 625 | 1125 | 63 |

| DYG100-100 | 100 | 100 | 250 | 350 | 180 | 100 | 140 | 58 | 63mpa |

| DYG100-160 | 160 | 310 | 470 | 63 |

| DYG100-200 | 200 | 350 | 550 | 78 |

| DYG100-300 | 300 | 450 | 750 | 96 |

| DYG100-500 | 500 | 650 | 1150 | 130 |

| DYG150-100 | 150 | 100 | 260 | 360 | 219 | 125 | 180 | 58 | 63mpa |

| DYG150-160 | 160 | 320 | 480 | 69 |

| DYG150-200 | 200 | 360 | 560 | 86 |

| DYG150-300 | 300 | 460 | 760 | 103 |

| DYG150-500 | 500 | 660 | 1160 | 255 |

| DYG200-100 | 200 | 100 | 285 | 385 | 240 | 150 | 200 | 96 | 63mpa |

| DYG200-160 | 160 | 345 | 505 | 103 |

| DYG200-200 | 200 | 385 | 585 | 116 |

| DYG200-300 | 300 | 485 | 785 | 161 |

| DYG200-500 | 500 | 685 | 1185 | 221 |

Description of double acting jack

The double acting jack (double acting jack) produced by our

company, especially in large projects, is easy to operate and

control and hydraulic jack, designed with safety pressure retaining

device, built-in pressure relief valve to prevent overload, in

order to protect the jack for safe operation. The connection of the

device is made of high pressure rubber hose and threaded joint. The

utility model has the advantages of quick use and overcoming the

shortcoming of oil leakage of fast traditional joints.

Method of use

- If the oil volume of the pump body is insufficient, it is necessary

to add working oil to the pump before it can work

- Estimate lifting weight, avoid overload use by all means

- Determine the center of gravity of the lifting weight, choose the

lifting point of the jack, at the same time must consider whether

the soft and hard degree of the ground pad with tough wood, so as

to avoid the risk of dumping when lifting

- After jacking up the weight, the weight shall be firmly supported

by tough wood in time. Jacks shall not be used as supports to avoid

the risk of dumping due to unbalanced load

- When in use, firstly connect the quick joint of the manual pump

with the top, then select the position and tighten the drain screw

on the oil pump to work. Unscrew the drain screw and unload the

cylinder

Company Profile

Established in 1993, Yixing Boyu Electric Power Machinery Co., Ltd.

is a manufacturer specialized in the research, development and

production of Electric Power Machinery, CE certified.

We are located in beautiful and rich city: Yixing city. We are a

High-tech enterprise in Jiangsu Province, with convenient

transportation access. All of our products comply with

international quality standards and are greatly appreciated in a

variety of different markets throughout the world.

1. Main configurations of our machine are from Germany and USA

- Engine: American Cummins

- Main pump: German Rexroth

- Main motor& speed reducer: German Rexroth

- Tail bracket hoisting motor: American Eton

- Hydraulic meter: German

2. Our company have more than 25 years rich experience in this

field. Our product sells in distant markets: Sudan, Kenya, Angola,

Pakistan, Burma, India, Mexico, Germany etc. Our product is also

very popular in china.

3. We have one year quality guarantee, if internal components go

wrong within one year, we will change another for free.

4. We can supply the specific components to the buyers with cost

price after warranty period.

Company

Workshop

Construction Site