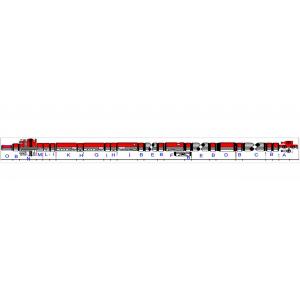

DST TEST STRING SHEMATIC AND DETAILED DESCRIPTION:

Drill-stem testing (DST) is a procedure used in the petroleum

industry to determine the productive capacity,and permeability of a

potential petroleum reservoir zone. It is comprised primarily of a

flow test on isolated rock formations that indicate the possibility

and presence of an oil reservoir. DST, is used primarily on

exploratory oil wells and gas wells, to ascertain their commercial

productivity

Halliburton type, all could change with Halliburton parts.

All equipments are produced according to API standard NACE

MRO175-2002

Type:full bore drill stem testing

service:H2S, CO2

Working pressure:10000psi ~ 15000psi

Working condition:High pressure high temperature(HPHT)

DESCRIPTION OD(in) ID(in) Top Connection Bottom Connection

A SURFACE TEST TREE 3-1/16"

5 3/4" Acme 5 3/4" Acme

B CROSSOVER 8.00 3.00 5 3/4" Acme 5 3/4" Acme

CROSSOVER 8.00 3.00 5 3/4" Acme 3-1/2"PH-6

CROSSOVER 5.00 2.25 3-1/2" PH-6 3-7/8"CAS

CROSSOVER 5.00 2.50 3-7/8"CAS 3-1/2" IF

CROSSOVER 5.00 2.25 3-1/2" IF 3-7/8"CAS

CROSSOVER 5.00 2.25 3-7/8"CAS 3-1/2"IF

CROSSOVER 5.00 2.50 3-1/2"IF 2-7/8" EUE

C 3-1/2" PH-6 TUBING 3.50 2.75 3-1/2" PH-6 3-1/2" PH-6

D SLIP JOINT 5.00 2.25 3-7/8"CAS 3-7/8"CAS

E DRILL COLLAR 4.75 2.2 3-1/2" IF 3-1/2" IF

F RD CIRCULATING VALVE 5.00 2.28 3-7/8"CAS 3-7/8"CAS

J RD SAFETY CIR. VALVE 5.00 2.28 3-7/8"CAS 3-7/8"CAS

H DRAIN VALVE 5.00 2.28 3-7/8"CAS 3-7/8"CAS

I CARRIER (2 Electronic) 5.00 2.25 3-7/8"CAS 3-7/8"CAS

CROSSOVER 5.00 2.28 3-7/8"CAS 3-7/8"CAS

G OMNI CIRCULATING VALVE 5.00 2.28 3-7/8"CAS 3-7/8"CAS

K SELECT TESTER VALVE 5.00 2.28 3-7/8"CAS 3-7/8"CAS

L BIG JOHN JAR (Closed) 5.00 2.28 3-7/8"CAS 3-7/8"CAS

M SAFETY JOINT 5.00 2.44 3-7/8"CAS 3-7/8"CAS

N 7" CHAMP PACKER 5.65 2.37 3-7/8"CAS 3-1/2"IF

O MULE SHOE 2.87 2.50 2-7/8" EUE

Certifications

Kingwell is a CNPC & SINOPEC & BV certified company, having

all the Quality Systems in place for design, planning,

manufacturing and quality monitoring & traceability to ensure

our products match the highest quality standards. We test our

products strictly according to the NACE MR 0175-2002 Standard and

our quality assurance period is 12 months.

Certificates endorsed by DNV/BV/ABS and Documents we can supply

with the shipments:

1. Pressure Test Certificate with Graph and time recorded.

2. Function Test

3. Rubber Products NACE Compliance

4. Material Mill Certificate and treatment characteristics

5. H2S Compliance

6. Service Manual

7. Parts Manual

8. Testing Procedures.

9. Open up type tool drawing for dressing purpose– if any.

Design & Development

Kingwell has an ongoing relationship with Xi'an Petroleum

University and built up long term cooperation with China Aerospace

Group for more than 10 years. Design Department is familiar with

CAD and Pro-E facilities and has on rolls qualified &

experienced engineers. Now, they are engaged in development of new

products as required in the market place. Kingwell' products are

validated in-house in a Test Well, a Sub-surface Type Test Facility

with simulated well conditions up to 15000 psi Differential

pressure , 400°F and Max 450°F.

Below are our cooperative partners.

Inspection and Test Facilities

We own the world-class facilities with professional laboratory

technicians. The main facilities are Surface Testing (Hydraulic

Testing Unit), high temperature heat treatment furnaces, API Gages

(Master & Working), Profile Projector, tensile testing machine,

pressure sensor and data acquisition system, Universal Testing

Machine, Hardness Tester, Nitrogen Pump, Function Test Pump,

Ultrasonic Thickness Tester etc. All the goods must be tested by

several processes and must be qualified when packed.

The followings are some pictures of Test Facility

Training and Field Supports

We have a team of well qualified and experienced field support

personnel for Training. According to customer's requirements, we

provide operation training service for our customers who purchase

our products.

Generally speaking, our customer training mainly includes

followings:

1) To know the basic knowledge of the products, such as the usage,

the working environments, the working principles, the structure,

ect.

2) To learn the operation and use of products.

3) To master the basic requirement of designs of tool strings and

of testing operation.