Product Details

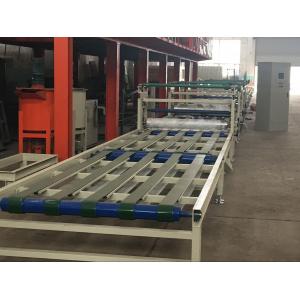

Automatic fiber cement board machine introduction |

FIBER CEMENT BOARD

Fiber Cement Board is a new construction material which has been pulping,

molding, compression, maintenance and so on. It is based on cement

and assist with proper fiber reinforced material. The products are

widely used in variety kinds of industrial and domestic

construction fields such as external, internal walls, ceilings,

sound insulation, and waterproof board for special facility.

Combined with keel and filler, it also can used for some framework

light board system construction, high-rise building, old building

renew, light type work shop, control room and laboratory. Because

of its good features like less building cycle, less energy, notable

economic benefit, fiber reinforced cement board are favorable all

over the world.

Fiber Cement Board Sandwich Panel Production Line/Mineral Fiber

Cement Ceiling Board Making Machine

Fiber cement board production line:

1.Fuel: electric.

2.Main material: cement,fiber glassmesh, sand, glue,

3.Standard finished board size:

Length:2400-2440 mm

Width: 1200-1220 mm

Thickness: 4-30 mm

4.fiber cement board density:

Three kinds: Low density; medium density and high density;

Low density cement boards are used for inner decoration;medium and

high density

fiber cement boards are used for external decoration or inner

decoration.

5.Production technology

Production technology of cement fiber board adopts slurry flowing

method or

hatschek method, with advanced technology and more simple

operation.

6.Main procedures:

A. Material processing, conveying and slurry making;

B. Slurry storage and premxing;

C. fiber cement Board making, conveying and stacking;

D. Premaintaining and demoulding;

E. Autoclave;

F. Drying;

G. Final processing and package.

| Item |

Unit |

Standard Fiber Cement Board |

| Density | g/cm 3 | <1.3 |

| Anti-bend strength | MPa | >9 |

| Heat conduction modulus | w/m.k | <0.29 |

| Anti-impact strength | kJ/mm 2 | >2.0 |

| Pull force of screw | N/mm | >75 |

| Dry shrinkage rate | % | <0.2 |

| Non-burn performance | | In accordance with standard GB8624 First Class Non-burn Material |

Advantages

| Advantages |

| Number | Item | Content |

| 1 | Low cost | Low labour and material costs |

| 2 | Long life | Up to 30 years |

| 3 | Recycling use | Reused for more than 10 times |

| 4 | Flexible layout | Layout adjusted according to your requirement |

| 5 | Environment protection | Environment-friendly materials used |

| 6 | Safe & Stable steel structure | Earthquake proof & Wind resistance |

Company Profile

Shandong Chuangxin Building Materials Machinery Co., Ltd., as a new

and high technology enterprise registered at provincial industrial

and commercial department and a modern group enterprise integrated

with scientific research, processing and trade mainly focus on

research, development and popularization of decorating technique,

building materials technology and machinery. Its many patent

products were sold throughout China and some were exported to

Russia, Southeast Asia, Hong Kong and Taiwan. We have had rich

assets and intellectual property rights after many years, and in

July 2004, our products were awarded as many laurels such as State

Key New Product by State Ministry of Science and Technology,

Ministry of Commerce, General Administration of Quality

Supervision, Inspection and Quarantine and State Environmental

Protection Administration. With this company got much economic

benefit and social benefit, so it enjoys high popularity and good

credit in the society. The company is composed of Machinery

Factory, Technology Development Center, Decorating Materials

Factory, Handicraft Development Center and Research Institute of

Paint and Coatings, and it establishes cooperative relationship

with Higher Educational Institutions and Scientific Research

Academy in Beijing and Shandong. With perfect scientific research

production base, rich material conditions and technical force and

acute market feeling, the company reformed boldly and strengthened

exchange and cooperation with the world, and at the same time made

its technology and equipment always meet requirements of changing

market. The above let this company ranks as a leading enterprise in

the same industry. In the information times filled with opportunity

and challenge, all employers of our company will abide by the

management ideas of “Take Market as Principle, Take Scientific

Technology as Forerunner” and carry forward the company spirit of

“Only Innovation can bring competitive power and vitality”, to work

towards to key technological breakthroughs and develop industry,

and will exploit, develop and create wonderful tomorrow together

with all friends on the new and high technology road.