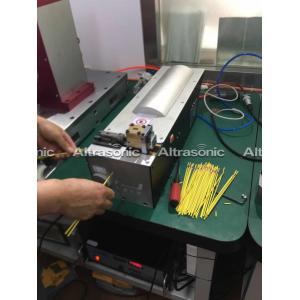

Low Noise 20 Khz Ultrasonic Wire Splicing Machine For Auto Industry Application

Add to Cart

Low Noise 20 Khz Ultrasonic Wire Splicing Machine For Auto Industry Application

Description:

Altrasonic ultrasonic wire splicer can be used for welding of metal wires, cooper and aluminum wires, pre-crimped wire, metal stranded wire, terminal, wire/conductor for battery etc. It can be widely used for applications like car, electronics, generator, communication devices, instrument and etc.

Specification:

| Model | Operating Frequency | Operating Pressure | Suitable Wire size | Power | Operating mode | Dimension | Weight |

| HS-2032JX-AT | 20KHZ | 1kgf/cm2-6.0kgf/cm2 | 5-25mm2 | 380v/16A | Manual | 900*600*110 | 45kgs |

| HS-2020JX-AT | 35KHZ | 1kgf/cm2-6.0kgf/cm2 | 1-12mm2 | 220v/10A | Manual | 200*550*250 | 35kgs |

Advantages:

1. Can be operated easily, no need for professions thus low labor cost.

2. Automatic program for welding process, high production efficiency.

3. Optimized welding process, no need of accessory material for welding, fast welding speed, and high energy efficiency.

4. Electronic protection circuit for safety;easy to operate

5. Compact design, advances structural design makes this machine light and portable

6. Welding tip with high quality steel, robust and durable

what is the difference between Ultrasonic metal welding machine and ultrasonic plastic welding machine ?

Firstly, the way of working is not the same. Generally, the vibration direction of the welding head in the ultrasonic plastic welding is perpendicular to the welding position. In the ultrasonic metal welding machine, the vibration direction of the welding head is parallel to the welding position. In some special cases, plastic welding can also be used in parallel directions, such as thinner plastic parts.

High power capacity, stable ultrasonic generator:

The first requirement for a stable ultrasonic generator is frequency automatic tracking. Frequency automatic tracking can ensure that the transducer system can work in resonance, that is, the welding head amplitude is maximized. The use of frequency automatic tracking technology, the replacement of molds and work without the need for FM, is the basic requirements for metal welding. A device with manually adjustable frequency adjustable inductance can basically meet the requirements.

Secondly, due to the application of metal welding machines to welding metals, higher requirements are placed on ultrasonic welding technology. Compared to ordinary plastic welding, the requirements for power capacity, power density, stability, and automatic control are not the same. level. Domestic ultrasonic plastic welding generators are basically self-excited circuits, typically represented by full-bridge circuits and half-bridge circuits commonly used in Taiwanese machines. The distinctive feature is a tuned inductor. If the existing mature technology for plastic welding is directly transferred to metal welding, its technical innateness will lead to unstable use of the product; its only advantage is that the price is cheap, but for the high requirements of the metal welding itself, This advantage is very pale.

The stable ultrasonic generator also requires: constant amplitude function and amplitude stepless adjustment. Constant amplitude function, which can ensure the consistency of welding, is the key to stable production; stepless adjustment of the amplitude is the basic to ensure the use of equipment, such as the ability to weld copper and weld aluminum materials on the same equipment through parameter adjustment.

High power capacity: Metal welding machines require high energy density relative to plastic welding machines and must have relatively high power capacity. For example, a 20 kHz machine requires basically more than 3000 W of power capacity. Many companies often have false claims for power capacity, so we only need to compare them with the plastic welding machines they do, because plastic welding machines are too high to be believed.

1. High-quality welding heads: Metal welding, as an industrial application, inevitably requires a long-life welding head.

2. High-quality control system: It has three basic control modes: welding energy, time, and altitude. A variety of quality control software meets different requirements.

3. Metal welding machines use high-quality transducers such as 20kHz transducers that must be able to withstand more than 3kw of load for long periods of time. Many companies' transducers use ordinary plastic welding transducers and are difficult to distinguish in appearance. This is irresponsible.

20Khz Ultrasonic Wire Splicer for Welding Metal Wires for Auto Industry Application