Add to Cart

20khz Titanium Blade Ultrasonic Cutting Knife For Food With

Different Sizes

Description:

20khz ultrasonic food cutting machine provides beautiful cutting

surface and with different sizes

Specification:

Frquency | 20kHz |

Power | 800w |

Input | AC110-240V, 50/60Hz |

Power Controller | stepping or continuous |

Length of the blade | 305mm |

Material Of Cutting Head | stainless steel, titanium alloy, alloy steel |

Accessories | foot switch, additional blade |

Cable Length | or customized |

The difference between traditional cutting and ultrasonic cutting:

Ultrasonic cutting machine is the use of wave energy for cutting

equipment, the main t feature is not to use the traditional edge.

The traditional cutting utilizes a tool with a sharp edge to press

the cutting material. The pressure is concentrated at the edge of

the blade, the pressure is very large, more than the shear strength

of the cutting material , then the material is cut open. As the

material is cut by a strong pressure, so the cutting tool edge

should be very sharp and the material itself has to bear the

relatively large pressure. Therefore the cutting effect for the

soft, flexible material is not good, especially more difficult for

sticky material.

Advantages:

♦Clear and clean cutting surface

Non-stick knife, the cut is smooth and tidy, will not deform the

burnt

♦Reducing wastes of food and down time

The food is continuously cut, and the food does not need to stop

during the cutting process.Use ultrasonic technology to reduce the debris generated by food

during cutting, thus reducing downtime cleaning time and increasing

production efficiency

♦Sanitary production environment

♦Easy to use with automated line

Can be used on existing food processing and packaging equipment

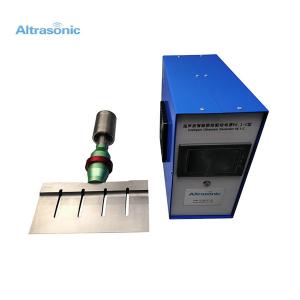

Ultrasonic Components:

Typical ultrasonic food cutting components include four major

elements: a power supply, a converter, a booster and a cutting horn

Application:

♦ Bakery and snack foods,

♦ Candy and confectionery cheese/Fish/Prepared

meat/Vegetable/Health Bars;

♦ Chocolates, sandwich and wrap cutting;

♦ Dry fruit;

♦ Poultry;

♦ Potted;

♦ Processed meat;

♦ Ground meat;

Detailed images:

After sale serivce:

Conforming to the spirit of "Service First", ALTRASONIC provides

lifetime maintenance to its products for as long as they are used

by customers. Altrasonic’s service team is 24/7 available for

support. Our well trained and experienced service engineers advise

and support on-line or if necessary on location. Whether a

custom-made production line or a standard machine: we always ensure

that production can be resumed as soon as possible.