Add to Cart

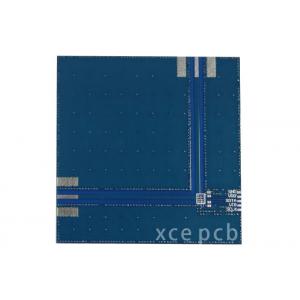

60GHz Receiver And Transmitter Module 0.508mm 2oz copper pcb Board

, Blue Soldermask

Quick detail:

| Origin:China | Special: Taconic material |

| Layer:4 | Thickness:0.79mm |

| Surface: ENIG | Hole:0.8 |

TACONIC company is the world's largest production of PTFE CCL

manufacturer, with a glass woven cloth coated with PTFE patent, is

the PTFE microwave CCL industry, one of the technology leader, and

its microwave CCL's dielectric constant To 2.17-10.0, occupying the

global antenna sheet market share of more than 80%.

TACONIC high-performance insulation materials for the microwave,

radio frequency (RF) and high-speed digital signal processing

market PTFE / woven glass fiber woven sheet. This material can be

used in LNAs, LNBs, PCS / PCN antenna systems, Global Positioning

System (GPS) and UMTS antenna systems, as well as power amplifiers,

passive components, collision avoidance radar systems, aeronautical

telemetry and phase control Array radar system.

High Speed Design Frequency PCB Board Special high electromagnetic frequency circuit boards, in general,

can be defined as the frequency of the high frequency of 1GHz. Its

physical properties, precision, technical parameters required is

very high, commonly used in automotive anti-collision systems,

satellite systems, radio systems, etc.

The basic characteristics of a high frequency board material

requirements are the following:

(1) dielectric constant (Dk) must be small and very stable, usually

the smaller the better signal transfer rate and the dielectric

constant of the material

Inversely proportional to the square root of high dielectric

constant is likely to cause the signal propagation delay.

(2) the dielectric loss (Df) must be small, mainly affect the

quality, the smaller the dielectric loss signal transmission of the

signal loss is smaller.

(3) as far as possible consistent with the coefficient of thermal

expansion of the copper foil, copper foil separated because of

inconsistency will cause changes in the hot and cold.

(4) to low water absorption, high water absorption will affect the

dielectric constant and dielectric loss when damp.

(5) Other heat resistance, chemical resistance, impact strength,

peel strength, etc. must also be good.

Microwave Antenna 4 Layer PCB Board,Radio frequency (RF) and microwave PCB’s are a type of PCB designed

to operate on signals in the megahertz to gigahertz frequency

ranges (medium frequency to extremely high frequency). These

frequency ranges are used for communication signals in everything

from cellphones to military radars. The materials used to construct

these PCB’s are advanced composites with very specific

characteristics for dielectric constant (Er), loss tangent, and CTE

(co-efficient of thermal expansion).

High frequency circuit materials with a low stable Er and loss

tangent allow for high speed signals to travel through the PCB with

less impedance than standard FR-4 PCB materials. These materials

can be mixed in the same Stack-Up for optimal performance and

economics.

Parameter:

The multi-layer structure of Solus building material weaving has

the following characteristics:

Light weight

Its weight is only a small part of traditional building materials

high strength

Glass fiber is the highest strength of the textile fabric, it is

even more than the same diameter of the wire but also solid

Flexibility

Unlike most solid construction materials, the soft Solus products

can be stretched into a variety of dynamic arc shapes

Light transmission

Through the inside and outside the surface of uniform light

transmission, the formation of a soft light scattering

Low maintenance

In the weaving period, only a very small amount of cleaning work.

Because the surface of the non-woven fabric is strong, while taut,

so the rain will wash away the dust

The surface is completely inert

Harsh environments, such as molds, acid rain, etc., will not work

on the surface of the weave

Weldability

Each fabric framework will be welded together into a large roof.

The strength of the weld will be greater than the fabric itself

The use of a long period

During its lifetime, the PTFE-coated glass cloth was almost

non-degraded. At present, Solus weaving is estimated to be usable

for at least 25 years

Fire performance

Solus weaves a Class A fire rating, while still maintaining a

strong light transmission