Add to Cart

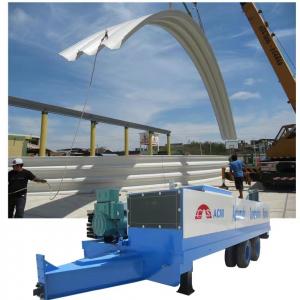

0.8-1.5mm Thickness ACM No-grid 914-610 K Span Arch Roof Machine with 36 Meters Proper Span

Technical Parameter

Item NO. | Description | Offered Specification |

1 | Product Line speed | 0-10 m per min |

2 | Suitable material thickness | 0.8--1.5 mm |

3 | Raw material | Pre-paint Color Steel Coil yield strength≤G250MPa |

4 | Dimension | About 10400mm * 2250mm * 2300mm |

5 | Levelling device | 7 roller levelling |

6 | Roller stations(stages) | 16 stations |

7 | Roller material | bearing steel, quenching treatment |

8 | Shaft diameter | Φ76mm ,material is 45# forge steel |

9 | Transmission | By chain 1.2 inch 20A double chain with longer shafts |

10 | Material of chain | 45# forged steel with frequency quenching, 12A |

11 | Material of cutting | Cr12Mov with quench HRC58-62° |

12 | Main motor power | 7.5kw |

13 | Motor power of hydraulic station | 5.5kw |

14 | Hydraulic station pressure | 12Mpa |

15 | Machihne Weight | 10 Ton |

15 | Tolerance | 6m+-1.5mm |

16 | Frame | H Beam |

Serial No. | Commodity & Description | Quantity |

1 | 5 ton manual De-coiler | 1 set |

2 | Leveing guiding devide | 1 set |

3 | Servo feeding device | 1 set |

4 | Main roll forming machine | 1 set |

5 | Hydraulic station | 1 set |

6 | Cutting device | 1 set |

7 | Finished products tabel | 1 set |

8 | PLC control system | 2 sets |

9 | Out tables | 1 set |

10 | Spare parts | 1 set |

Machine Description

The no girder arch roof roll forming machine is designed and built to produce large span steel sheet for

roofing panel. It is comprised of mechnical expansion decoiler, roll forming machine unit, hydraulic mould

cutting device, curving panel machine unit, PLC control system, hydraulic system, run-out tables for

straight and curve panels and all other accessories. Customer can choose mobile truck as foundation for

flexible use.

Main Fetures & Components of the Machine

1. The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and process as a whole after welding, it has the ability of strong loading and stable operation when running the machine.

2. All the components of the machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3. We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

4. It's very easy to install the equipment and suitable for producing in the factory.

5. The machine has features of low noise and high efficiency.

Standard Profile Drawing

Forming Machine Picture