Automatic tank level gauge ATG for petrol station management/ magnetostrictive liquid level .Float type meter/sensor

Add to Cart

Automatic tank level gauge ATG for petrol station management/ magnetostrictive liquid level .Float type meter/sensor

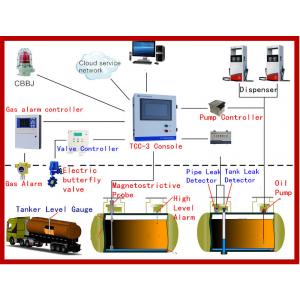

Gas staion control system digital diesel fuel tank level gauge

It is a professional instrument, monitoring up to twelve tanks (eight tanks is standard) with the combination of Magnetostrictive probe. It can monitor fuel level, water level, temperature and other information of real time, which can help you acquire detailed knowledge of the inventory and delivery situation, and increase your efficiency. This product has been awarded the approval from PCEC.

It provides powerful functions for management: 24 hours real time monitoring the fuel level, water level, temperature and inventory. Display dynamically the variations of fuel and water level in graphic. The audible and visual alarm is there for security. It enjoys a fuel tank leak detection function. Calculate the fuel delivery volume accurately. It’s very convenient to print all kinds of reports.

The touch screen of the console features a simple interface which makes it easy for customers to use, text on menus and reports are displayed in English. Please read the operation manual before usage.

| Items | Performance index |

| L×W×H | 310mm×220mm×105mm |

| Supply Voltage | AC 120V~265V 50Hz |

| Ambient Temperature | -20℃~+60℃ |

| Ambient Humidity | 20%~85% |

| Screen Dimension | 7 Inch |

| Display Mode | English,graphic,LCD |

| Monitor up to | 1~8 (Max 12) |

| I/Orelays | 2 |

| Transmission Mode with Central Control System | RS-232 (within 15m) |

| Transmission Mode with Magnetostrictive probe | RS-485 (within 1200m) |

The main functions is as follows

1.Authority Management: It’s only need a password to setup the Magnetostrictive Probe parameter, others free operation.

2.Parameter Setting: Customers can setup parameters about tank, time and tank volume table.

3.Auto-monitoring: Monitoring up 1~8 (max 12) tanks, display all the tank information of real time.

4.Automatic Gauge: Display fuel level, water level, temperature, inventory and ullage, monitor the fuel delivery condition of real time. Display dynamically the change of fuel and water level with graphic and scale.

5.Inventory Report: Users can inquire and print the inventory at any moment.

6.Manual Delivery: Set up fuel delivery parameter, an automatic generating delivery report would be printed after delivery.

7.Tank Volume Table Edition: Users can input the tank volume table from computer, or input it word by word through touch screen. Tank with the same volume can be copied in the system, need not input one by one.

8.Static Leak Detection:During the idle time of the gas station, operator can do the leak detection ( 0.38 L/h ) for the tank ,also can print the delivery report.

9.Alarm: High fuel level alarm, low fuel level alarm, high water level alarm, fuel temperature upper limit alarm, fuel temperature lower limit alarm. With audible and visual alarm signal, audible alarm can be removed. It can connect with an outside explosion-proof ringer to avoid the fuel spilled.

10.Parameter Inquiry: Users can inquire the tank parameter, time parameter, and tank volume parameter.

11.Shift Exchange: Click the “Shift” button to accomplish shift exchange.

12.Print: All the report can be printed with an internal printer.

13.Communication Interface: Reserve two RS-232 port; achieve fuel buy, sale and stock data upload.

14.ntelligent control of oil pump: Control oil pump though use of relay avoiding that the oil spilled or pumpdown.

15.It enjoys tank volume table calibration function.

PROBE PERFORMANCE

| Item | SYW-A |

| Purpose | To measure product level, water level and temperature |

| Titles of medium | Gasoline, diesel, kerosene, ethanol , water etc. |

| State of medium | Liquid |

| Explosion-proof grade | ExiaIIBT4 (Intrinsically safe) |

| Pressure range | -0.02Mpa~0.6Mpa |

| Certificate | PCEC Conformity Certificate of Explosion-proof / Permit of Manufacture Measuring Instruments |

| Temperature | -40℃~70℃ |

| Product Level Accuracy | ±0.3mm |

| Water Level Accuracy | ±0.3mm |

| Temperature Accuracy | ±0.2℃ |

| Height Resolution | 0.023mm |

| Repeatability | ±0.1mm |

| Temperature Effect | Error<0.2mm |

| Vibration Effect | Error<0.5mm |

| Lowest Product Inactive Zone | 2.5'' floater-180mm |

| Lowest Water Inactive Zone | 2.5'' floater-25mm |

| Measured Variable | Product level, interface level and temperature of 5 sensors and average temperature |

| Probe Length | 600~4000mm |

| Method of Communication | RS-485 |

| Probe Material | 1Cr18Ni9Ti |

| Power Supply | +24~26VDC |

| Protection Class of Probe Canister | IP67 |

| Max Communication Distance | 1200m |

Installion

It is a professional instrument, monitoring up to twelve tanks (eight tanks is standard) with the combination of Magnetostrictive probe. It can monitor fuel level, water level, temperature and other information of real time, which can help you acquire detailed knowledge of the inventory and delivery situation, and increase your efficiency. This product has been awarded the approval from PCEC.

It provides powerful functions for management: 24 hours real time monitoring the fuel level, water level, temperature and inventory. Display dynamically the variations of fuel and water level in graphic. The audible and visual alarm is there for security. It enjoys a fuel tank leak detection function. Calculate the fuel delivery volume accurately. It’s very convenient to print all kinds of reports.

The touch screen of the console features a simple interface which makes it easy for customers to use, text on menus and reports are displayed in English. Please read the operation manual before usage.

| Items | Performance index |

| L×W×H | 310mm×220mm×105mm |

| Supply Voltage | AC 120V~265V 50Hz |

| Ambient Temperature | -20℃~+60℃ |

| Ambient Humidity | 20%~85% |

| Screen Dimension | 7 Inch |

| Display Mode | English,graphic,LCD |

| Monitor up to | 1~8 (Max 12) |

| I/Orelays | 2 |

| Transmission Mode with Central Control System | RS-232 (within 15m) |

| Transmission Mode with Magnetostrictive probe | RS-485 (within 1200m) |

The main functions is as follows

1.Authority Management: It’s only need a password to setup the Magnetostrictive Probe parameter, others free operation.

2.Parameter Setting: Customers can setup parameters about tank, time and tank volume table.

3.Auto-monitoring: Monitoring up 1~8 (max 12) tanks, display all the tank information of real time.

4.Automatic Gauge: Display fuel level, water level, temperature, inventory and ullage, monitor the fuel delivery condition of real time. Display dynamically the change of fuel and water level with graphic and scale.

5.Inventory Report: Users can inquire and print the inventory at any moment.

6.Manual Delivery: Set up fuel delivery parameter, an automatic generating delivery report would be printed after delivery.

7.Tank Volume Table Edition: Users can input the tank volume table from computer, or input it word by word through touch screen. Tank with the same volume can be copied in the system, need not input one by one.

8.Static Leak Detection:During the idle time of the gas station, operator can do the leak detection ( 0.38 L/h ) for the tank ,also can print the delivery report.

9.Alarm: High fuel level alarm, low fuel level alarm, high water level alarm, fuel temperature upper limit alarm, fuel temperature lower limit alarm. With audible and visual alarm signal, audible alarm can be removed. It can connect with an outside explosion-proof ringer to avoid the fuel spilled.

10.Parameter Inquiry: Users can inquire the tank parameter, time parameter, and tank volume parameter.

11.Shift Exchange: Click the “Shift” button to accomplish shift exchange.

12.Print: All the report can be printed with an internal printer.

13.Communication Interface: Reserve two RS-232 port; achieve fuel buy, sale and stock data upload.

14.ntelligent control of oil pump: Control oil pump though use of relay avoiding that the oil spilled or pumpdown.

15.It enjoys tank volume table calibration function.

PROBE PERFORMANCE

| Item | SYW-A |

| Purpose | To measure product level, water level and temperature |

| Titles of medium | Gasoline, diesel, kerosene, ethanol , water etc. |

| State of medium | Liquid |

| Explosion-proof grade | ExiaIIBT4 (Intrinsically safe) |

| Pressure range | -0.02Mpa~0.6Mpa |

| Certificate | PCEC Conformity Certificate of Explosion-proof / Permit of Manufacture Measuring Instruments |

| Temperature | -40℃~70℃ |

| Product Level Accuracy | ±0.3mm |

| Water Level Accuracy | ±0.3mm |

| Temperature Accuracy | ±0.2℃ |

| Height Resolution | 0.023mm |

| Repeatability | ±0.1mm |

| Temperature Effect | Error<0.2mm |

| Vibration Effect | Error<0.5mm |

| Lowest Product Inactive Zone | 2.5'' floater-180mm |

| Lowest Water Inactive Zone | 2.5'' floater-25mm |

| Measured Variable | Product level, interface level and temperature of 5 sensors and average temperature |

| Probe Length | 600~4000mm |

| Method of Communication | RS-485 |

| Probe Material | 1Cr18Ni9Ti |

| Power Supply | +24~26VDC |

| Protection Class of Probe Canister | IP67 |

| Max Communication Distance | 1200m |

Installion

It is a professional instrument, monitoring up to twelve tanks (eight tanks is standard) with the combination of Magnetostrictive probe. It can monitor fuel level, water level, temperature and other information of real time, which can help you acquire detailed knowledge of the inventory and delivery situation, and increase your efficiency. This product has been awarded the approval from PCEC.

It provides powerful functions for management: 24 hours real time monitoring the fuel level, water level, temperature and inventory. Display dynamically the variations of fuel and water level in graphic. The audible and visual alarm is there for security. It enjoys a fuel tank leak detection function. Calculate the fuel delivery volume accurately. It’s very convenient to print all kinds of reports.

The touch screen of the console features a simple interface which makes it easy for customers to use, text on menus and reports are displayed in English. Please read the operation manual before usage.

| Items | Performance index |

| L×W×H | 310mm×220mm×105mm |

| Supply Voltage | AC 120V~265V 50Hz |

| Ambient Temperature | -20℃~+60℃ |

| Ambient Humidity | 20%~85% |

| Screen Dimension | 7 Inch |

| Display Mode | English,graphic,LCD |