Add to Cart

Our helical pile is characterized by its high quality steel. In an

era where many companies choose to source their raw materials from

Asia, the Techno Metal Post team is committed to purchasing North

American steel and manufacturing its piles. Our piles are

manufactured using structural steel according to ASTM A500 grade C,

CAN/CSA-G40.21-98 and CSA W47.1 standards. Their design allows for

maximum use of soil capacity. They have been load tested according

to ASTM-D1143 and ASTM-D3689 standards in several types of soils

around the world.

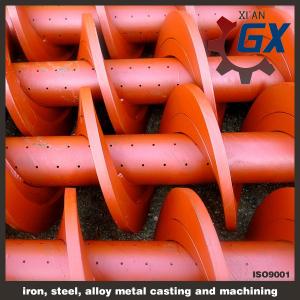

Rock drilling auger bit and concrete auger specification

|

One of the major challenges a helical pile foundation must face is

resisting ground movements. When the ground moves, it tends to pull

or push on the shaft of the pile. Techno Metal Post designed and

developed this proprietary green-coloured sleeve that reduces the

grip of ground movements on the pier.

The sleeve size is adapted to that of the pile and is installed

around the pier when it is screwed into the soil. Once in place,

the sleeve slides up and down the pile with natural ground

movements. It allows the pile to remain perfectly stable during

freezing, thawing or drought periods.

As with our helical piles, Techno Metal Post has its own plastics

department for the manufacturing of our exclusive sleeves in

Quebec, in a variety of sizes. This gives us complete control over

the quality of the product and, consequently, that of your helical

pile foundations.

In keeping with the company’s philosophy, which is to offer strong

and durable products, Techno Metal Post has specially developed

technologies using the principle of cathodic protection to ensure

that even helical piles installed in corrosive soils are protected

for the long term.

Hot-dip galvanizing provides long-term protection for foundation

piles.

Techno Metal Post goes one step further by offering alternatives to

galvanizing.

Installing a cathodic protection system ensures the integrity of

the structure for the desired time period.

Techno Protection offers two products for the protection of helical

pile foundations:

Ring AnodesTMare ring-shaped magnesium sacrificial anodes installed on the shaft

of the pile. They provide a one-time cathodic protection for small

structures.

Ring Anodes use the intrinsic electrochemical properties of metals.

Since the magnesium anode is from material inferior to steel, it

consumes itself, thereby releasing an electrical current that

prevents the structure from corroding.

Spin AnodesTMare impressed current anodes that are screwed into the ground like

piers. Therefore, they do not require excavation and are available

in a variety of sizes depending on the current needed.

Spin Anodes are made from alloys superior to steel and diffuse an

electrical current produced by an external rectifier, thereby

ensuring continuous protection of the buried steel structure.

Techno Protection is a sister company of Techno Metal Post. It is

specialized in corrosion prevention, investigation and control.

Production Process

Production of spiral pile raw materials are: Q235 pipe. Screw pile

usually after cutting, deformation, welding, pickling, galvanizing

and other processes in order to produce qualified pile, which

pickling, galvanizing corrosion process is important, a direct

impact on the life of screw pile .

Life spiral pile will determine the level of processing pile of

metal, such as the use of the pipe is trachoma, the existence of

Weld, weld width pile affect the quality of future life and

subsequent processing, pickling is an important preservative

process foundation, while HDG time

, Thickness of the surface layer of galvanized pile affect the

quality of preservative treatment. Under normal circumstances, the

screw can be used to pile 20--30 years. Use of the environment and

the use of processes, but also affect the life of the pile, such as

the degree of acid soil, the process operation is appropriate,

inappropriate

Land use, will lead to the destruction of metal pile surface, the

metal protective layer is damaged, leading to accelerated corrosion

of metal pile, reducing service life

Detail show