Add to Cart

wood shredding machine/wood shredder/single shaft shredder is a widely used type of machine. It consists of a single, solid

shaft with square blades bolted into it. This shaft rotates at

about 74-83 RPM, depending on the model, and these blades pass

through a bed knife on the base of the cutting chamber. A hydraulic

ram continually pushes the material against the shaft of the

shredder for continuous cutting. It is an ideal machine for

plastics, paper, wood, fiber, rubber, organic waste a wide variety

of non metallic materials.

The size of the machine required for each project depends on the

initial size of the material, capacity and the final particle size

desired.

wood shredding machine/wood shredder/single shaft shredder is

almost always used with a screen, which retains the material in the

cutting chamber to reduce the material even further. The standard

cut on a single shaft shredder is 25-40mm.

Application:

The S series range of wood shredding machine/wood shredder/single

shaft shredder is our conventional range of small to medium size

single shaft shredders. Controlled by microcomputer (PC), featuring

start, stop, reverse functions. It is fitted with an automatic

overload return mechanism to prevent damage to rotor and other

parts. Suitable for processing a wide range of materials including:

Plastic lump/purging, Plastic boards, Circuit boards, Plastic

barrels, Wood, Fibre, Rubber, Films.

The machine is suitable to process very big size of waste

furniture, such as fiber board or shaving board (particleboard) in

furniture industry, timber harvesting, wood cutting remains (branc

hes), wood processing remains(saw mill residue), waste wood

pallets, and even other no wood material (reed, bamboo).

2. The machine with big feeding mouth, it can put the big plastic

product freely.

3. The rotary blade and cutting blade and blade edge with special

design, it can get very high efficiency and high capacity

4. The machine is control by PLC system, . The knife can rotated in

opposite direction, and also can close automatic if something

unexpected happen, with very high safety service

5. The machine running slowly with low noise and low dust

6. The knife material is high quality tool steel, with long

lifetime.

We specialize in this crusher and environment-protection field many

year. with best quality, best service and competitive price,

More service we can provide:

1. Customize & OEM is available.

2. Consumable parts for free distribution.

3. Our engineer are available to service oversea.

4. Professional Free Design

5. Respect clients; Devote ourselves to improving the total value

6. 12 months warranty

What about the quality of your products?

1. we have a special training for each worker.

2. we use China famous brand spare parts to cast the machine.

3. have a trial test run before delivery the machine out of the

factory.

How about the shipping and package?

1. we arrange shipment usually according to your special

requirements.

2. usually wooden case or plywood package.

How to get a suitable machine?

1. what is the raw material

2. the dimension of the input material and outpout material

3. the capacity,and power condition.

Tell me those data, we can help you choose the Waste type Shredder

for you.

Please feel free to contact me any time with any questions,

We are waiting for you!

Single Shaft Shredder Introduction:

Single shaft shredder is available to recycle wide range of material. It is an ideal

machine for plastic, paper, wood, fiber, rubber, organic waste a

wide variety of non-metallic materials. As per our customer’s

requirements, such as the input size of materials. Capacity and the

final output size etc. We could work out a suitable proposal for

our clients. After being shredder by the machine, the output

material could be used directly or go int to the next step of size

reduction.

With the function of PLC microcomputer control system, it is

possible to control automatically start, stop. Automatic reverse

sensors to protect the machine against over loading and jamming.

The output capability typically range between 300kg/hr -5,000kg/hr+

depending on the different model and different materials.

Single Shaft Shredder Application:

Plastic: Film; Jumbo Bag; PET Bottle; Plastic Barriers; Plastic

Pipe; Plastic Boards

Hard Plastic: Plastic Lump (Purgings); Fiber, High Strength

Engineering Plastics ( ABS, PC, PPS, etc.)

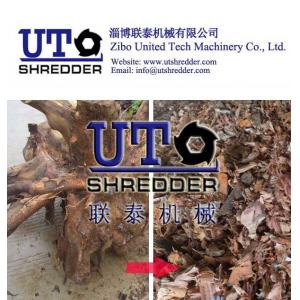

Wood:

Timber; Tree Root; Wood Pallets; Wood Package, etc.

Industrial Solid Waste:

Cable; Light Metal, like Aluminum Can, Aluminum Scrap, etc. White

Goods, like TV Shell, Washing Machine Shell, Refrigerator Body

Shell, Computer Shell, Circuit Board, etc. Solid Waste, like

Household Garbage, Medicinal Waste, Industrial Waste, etc.

Others: Rubber, Textile, Fiber & Glass Products,Paper: etc.

| Model | S2250 | S2260 | S3060 | S3080 | S4080 | S40100 |

| dimension L/W/H(mm) | 1780*1190*1690 | 1780*1290*1690 | 2455*1478*1700 | 2455*1678*1700 | 2825*1747*1875 | 2825*2004*1875 |

| Cutting Chamber Size(mm) | 790*500 | 790*600 | 1200*600 | 1200*800 | 1400*800 | 1400*1000 |

| RAM(mm) | 500 | 600 | 600 | 800 | 800 | 1000 |

| Rotor Blade Diameter(mm) | 220 | 220 | 300 | 300 | 390 | 390 |

| Rotor Ratate Speed (r/min) | 80 | 80 | 80 | 80 | 80 | 80 |

| Rotor Blade Size(mm) | 35*35*23 | 35*35*23 | 40*40*25 | 40*40*25 | 46*46*30 | 46*46*30 |

| Rotor Blade Quantity (PCS) | 20+4 | 24+4 | 30+4 | 42+4 | 42+4 | 54+4 |

| Counter Quantity(PCS) | 2+2 | 2+2 | 2 | 2 | 2 | 25 |

| Rotor Motor Power(KW) | 15 | 18.5 | 22 | 30 | 37 | 45 |

| Material Return Power(KW) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 5.5 |

| Model | S40120 | S40150 | S48150 | S48200 | S48250 | |

| dimension L/W/H(mm) | 2825*2564*1875 | 2825*2964*1935 | 3255*4415*2720 | 3255*4415*2720 | 3255*4615*2720 | |

| Cutting Chamber Size(mm) | 1400*1200 | 1400*1500 | 1650*1500 | 1650*2000 | 1650*2500 | |

| RAM(mm) | 1200 | 1500 | 1500 | 2000 | 2500 | |

| Rotor Blade Diameter(mm) | 390 | 390 | 480 | 480 | 480 | |

| Rotor Ratate Speed (r/min) | 80 | 80 | 80 | 80 | 80 | |

| Rotor Blade Size(mm) | 46*46*30 | 46*46*30 | 60*60*30.5 | 60*60*30.5 | 60*60*30.5 | |

| Rotor Blade Quantity (PCS) | 66+4 | 90+4 | 90+4 | 114+4 | 144+4 | |

| Counter Quantity(PCS) | 2 | 3 | 3 | 4 | 5 | |

| Rotor Motor Power(KW) | 55 | 75 | 90 | 75+75 | 90+90 | |

| Material Return Power(KW) | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | |

| Model | S66150 | S66200 | S66250 | S66300 | S66400 | |

| dimension L/W/H(mm) | 4100*3450*3000 | 4100*3950*3000 | 4100*4450*3000 | 4100*5500*3000 | 4100*6800*3000 | |

| Cutting Chamber Size(mm) | 1550*1500 | 1550*2000 | 1550*2500 | 1550*3000 | 1550*4000 | |

| RAM(mm) | 1500 | 2000 | 2500 | 3000 | 4000 | |

| Rotor Blade Diameter(mm) | 660 | 660 | 660 | 660 | 660 | |

| Rotor Ratate Speed (r/min) | 80 | 80 | 80 | 80 | 80 | |

| Rotor Blade Size(mm) | 60*60*30.5 | 60*60*30.5 | 60*60*30.5 | 60*60*30.5 | 60*60*30.5 | |

| Rotor Blade Quantity (PCS) | 126+4 | 158+4 | 225+4 | 291+4 | 363+4 | |

| Counter Quantity(PCS) | 3 | 4 | 5 | 6 | 8 | |

| Rotor Motor Power(KW) | 75+75 | 90+90 | 110+110 | 132+132 | 160+160 | |

| Material Return Power(KW) | 7.5 | 7.5 | 7.5 | 7.5 | 7.5 |

Note:

1. The voltage about the power supply can be selected by the customer’s specific requirements.

The shredder capacity can be influenced by the material compostion and output size.