Add to Cart

Inconel Nickel-Chromium Alloy 625

Inconel Nickel-Chromium Alloy 625 is a highly corrosion and heat resistant alloy with excellent mechanical properties ideal for use in high temperature applications such as heat-treating, chemical processing, and nuclear reactor components. The addition of molybdenum and niobium increases the strength and corrosion resistance of the nickel-chromium base, imparting a stiffening effect that eliminates the need for precipitation-hardening treatments. AE Alloys™ are available in numerous forms such as bar, wire, sheet, tube, strip, and foil, in standard and custom dimensions. American Elements produces to many standard grades when applicable, including Mil Spec (military grade); ACS, Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available, as is additional research, technical and ety (MSDS) data.

Chemical composition:

| % | Ni | Cr | Mo | Fe | C | Mn | Si | P | S | Co | Nb+Ta | Al | Ti |

| min | 58.0 | 20.0 | 8.0 | 3.15 | |||||||||

| max | 23.0 | 10.0 | 5.0 | 0.10 | 0.50 | 0.50 | 0.015 | 0.015 | 1.00 | 4.15 | 0.40 | 0.40 |

Physical properties:

| Density | 8.44 g/cm3 |

| Melting range | 1290-1350℃ |

| Form | ASTM |

| Rod and bar | B 446 |

| Plate, sheet and strip | B 443, B 906 |

| Seamless pipe and tube | B 444, B 829 |

| Welded pipe | B 705, B 775 |

| Welded tube | B 704, B 751 |

| Welding fitting | B 366 |

| Billet and bar for reforging | B 472 |

| Forging | B 564 |

Features:

Inconel 625 has excellent strength at temperatures up to 816℃. At higher temperatures, its strength is generally lower than that of other solid solution strengthened alloys. Inconel 625 has good oxidation resistance at temperatures up to 980℃ and shows good resistance to aqueous corrosion, but is relatively moderate compared to other more capable corrosion resistant alloys.

Applications:

Chemical plant, bellows, submerged marine components, weld overlays, power station scrubber systems, general corrosion applications for aggressive environments, combustion and ducting systems, fuel nozzles, after burners, aerospace components.

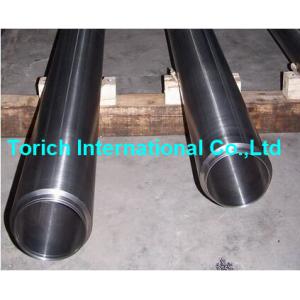

Product Pictures:

Company Introduction:

FAQ:

A: A professional steel pipes materials inventor, manufacturer and solution provider

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample of Cold drawn ERW DOM tubes ASTM A513 1010 1020 1026 for free charge but need pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us.