Add to Cart

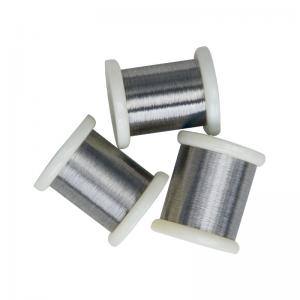

Nickel Plated Copper Wire Material:

Nickel plated copper wire is a type of wiring that is formed by

coating a copper wire with a thin layer of nickel. This wire

combines the advantageous properties of both copper and nickel,

making it an ideal choice for various applications.

The nickel coating meets the ASTM B355 standard. The basis material for nickel coated wire shall be copper wire

conforming to the requirements specified in Chinese Industrial

Standard GB/T3953-2009 and Japan Industrial Standard JIS3102, and

American Industrial Standard ASTM B33 Round Copper Wire For

Electrical Purposes.

Appliction:

The products are widely used in the industries of carbon film

resistors, metal film resistors, metal oxide film resistors, fuse

resistors, wire-wound resistors, glass glaze resistors,

piezoresistors, thermistors, non-inductive resistors,

photoresistors, thermal fuses, current fuses, capacitors, jumper

wires (jumpers), inductors, transformers, diodes, high-temperature

wires, marine cables, triple insulated wires, gas appliance

temperature sensors, welding wires, braided thread, grounding rod,

flexible flat cables (FFC) and so on.

Product Advantage:

1. The weldability is excellent; the ferrochrome soldering, wave

soldering and reflow soldering can be arbitrarily satisfied.

2. The plating is bright, smooth, uniform and moist; and the

binding force and continuity is good.

3. The core of the wire is made up of high-quality 99.9% pure copper,

which offers excellent electrical conductivity and thermal

stability.

4. The outer layer consists of a nickel plating, which enhances the

wire's corrosion resistance, hardness, and durability.

5. Withstand harsh conditions, including high temperatures,

vibrations, and mechanical stress, suitable for applications such

as marine and automotive industries.

6. The mechanical properties can be privately customized, to ensure

stable and reliable application in the different conditions.

Nickel Plated Copper Wire Characteristics:

Nickel Plated Copper Wire

Product standard: refer to GB / T 11019-2009, ASTM B355-95 or

according to customers' requirements

| Item | Diameter(mm) | |||

| 0.05<=d<=0.10 | 0.10<d<=0.23 | 0.23<d<=0.50 | 0.50<d<=3.26 | |

| Tolerance(mm) | ±0.002 | ±0.003 | ±0.004 | ±d% |

| Resistivity(Ωmm2/m) | GB/T11019-2009 Table 4 | |||

| Elongation(%) | GB/T11019-2009 Table 3 | |||

| Tensile Strength(MPa) | Soft:>=196 Hard:>=350 | |||

| Coating Thickness(um) | 0.3-5.0um | |||

| Appearance | No scratches, oil stains, exposed copper, oxidation, etc. | |||

| Packing | 8 inch,9 inch/Type 300, etc | |||

| Remark | According to customers' requirements | |||

| Item | Diameter(mm) | ||

| 0.05<=d<=0.09 | 0.09<d<=0.25 | 0.25<d<=0.50 | |

| Tolerance(mm) | ±0.003 | ±0.004 | ±0.005 |

| Resistivity(Ωmm2/m) | GB/T11019-2009 Table 4 | ||

| Elongation(%) | GB/T11019-2009 Table 3 | ||

| Tensile Strength(MPa) | >=196 | ||

| Coating Thickness(um) | 0.3-5.0um | ||

| Strand | 7-37 | ||

| Direction of Twist | Z(left) or S(right) | ||

| Lay length(mm) | 2.0-35 | ||

| Appearance | No scratches, oil stains, exposed copper, oxidation, etc. | ||

| Packing | Type 300. Type 400 | ||

| Remark | According to customers' requirements | ||