Add to Cart

Mineral processing operators use equipment to process mineral ores until the final form or a concentrate is produced. Commonly processed minerals include gold, silver, nickel and iron ore. Mineral-bearing ore is subjected to various processes to extract the minerals. The ore is first crushed, then processing equipment (such as screens, grinding mills, filters, flotation cells, tanks and conveyors) is used to extract concentrated minerals. At the end of the treatment process the minerals may be produced into their final form by smelting, or as a bulk concentrate in preparation for shipment from site.

Mineral processing operators may perform the following tasks:

Mineral processing operators can be involved in all aspects of mineral processing, including sampling and laboratory work. They often work in remote areas that are dusty, hot and noisy. Mineral processing operators work in teams, and shiftwork may be involved.

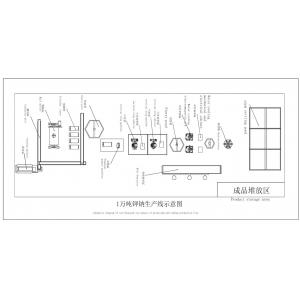

We Owns a complete set of small prototype mine beneficiation

equipmnet.

Provides free beneficiation test. If you have any ore, please post

15-20kg to our company for a free dressing experiment.Prepare for

beneficiationtest records. And collates them into a complete

beneficiation test report to you, for your reference.