Add to Cart

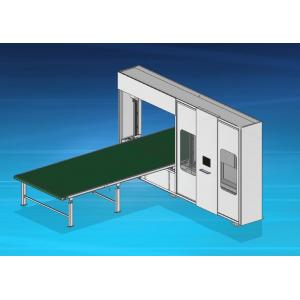

DTC-FK2012 Horizontal Fast Wire Cutting Machine For Rock Wool Miner Wool Flexible

OEM Horizontal fast wire cutting machine for insulation material with high speed

1. Applicable to: soft and hard PU, EPS, PE, PVC, EVA, rock wool and phenolic foam.

2. Cutting line: fast cutting line

3. The D&T Fastwire Contour Cutter is a versatile machine that

uses a high-speed moving abrasive wire that enables it to cut

complex 2D shapes from a variety of rigid and flexible foams. These

include flexible and rigid PU, EPS, PE, PVC, EVA, rock wool and

phenolic foams. All machines are powered by the superior D&T

Profiler software, which speeds up the design process and enables

operators to learn from foam blocks.

*Fast Wire Contour Cutter has a comprehensive safety system to

provide for accidents. Including: all motors stop when the safety

door is opened;

There are accident emergency buttons on the machine and the control

box; the braking system when the cutting line is broken.

specification:

Advanced automatic computerized foam contour cutting machine.

Foam can be cut into any 2D complex shape.

easy to control

This foam cutting machine is the most advanced automatic computer foam contour cutting machine at present, which can cut various shapes by computer system.

The eva foam contour cutter is operated by a computer, using CAD

software to design the shape of the foam block. Make full use of

the foam blocks, greatly saving the cost of raw materials (foam

blocks).

Besides CAD software, we also designed another drawing software by

our engineers, which is very easy to use. Operators need only

simple computer literacy training.

Equipped with high-precision servo system; fast cutting speed,

accurate cutting; improved work efficiency. 85% of the dust will be

collected in the bag during the cutting process with low noise.

Operating System: Windows XP

Design software: Auto CAD/self-developed CNC operating software.

Cutting software: D&T profile software.

application:

CNC rapid wire forming and cutting machine is specially developed for special thermal insulation materials used in the construction industry, and can be used for slicing and molding of various high-density foams.

It is the most ideal equipment for construction, interior decoration, advertising, toy model industry, aerospace industry model, furniture manufacturing and packaging. The control system is self-developed, worry-free service, tailor-made for you the most desired production equipment, is our goal.

Technical Specifications

| Max. Block Size | Length | 2500mm |

| Width | 1225mm | |

| Height | 1000mm | |

| Control Device | Industrial Computer | |

| Computer Operation System | Windows7 | |

| Software | D&T Profiler | |

| Acceptable File Formats | DXF/DWG | |

| Number of Cutting Wire | Dual Wire (Horizonal +Vertical) | |

| Cutting Wire Length | ~8500mm (Should be confirmed by maker by machine) | |

| Cutting Wire Diameter | 0.8~2.0mm | |

| Flying Wheel Diameter | 300mm | |

| Mainly Motor | ABB, 3kW*2pcs | |

| Running Speed of the wheel | 2860rpm | |

| Inverter | Panasonic, for 3kW motor | |

| Cutting Speed | 0~6m/min | |

| Precision | ±0.5mm | |

| Total Power | 11kW, 400/240V, 50Hz | |

| Gross Weight | 2800kg | |

| Overall Dimension | 5500*5500*2600 mm | |