Product Details

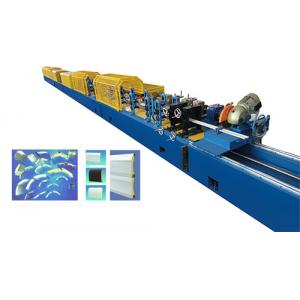

Polyurethane PU Foam Roller Shutter Slat Door Making Machine

PLC Computer Control Low Noise Rolling Shutter Door Roll Forming

Equipment With Hydraulic System

Description:

This producing line uses galvanized steel sheet, colored armor

plate or aluminum plate as the material plate. The products

produced by this machine are bright in colored, against fading,

resistant to rust, and be widely used for door and window in shops,

working departments, warehouses, and fire partition.

Technical data of roller shutter door roll forming machine

No | Item | Parameter |

1 | Material thickness | 0.25-0.35mm |

2 | Raw material | aluminum coil plate and colored steel |

3 | Material of rollers | GCr15 steel |

4 | Material of main shaft | 45# high quality steel,dia:Φ45mm |

5 | Driving | by 120# gear box |

6 | Cutting | fly tracking saw cutting |

7 | Machine Frame | H Beam Steel |

8 | Working speed | 10-15 m/min |

9 | Dimension | about 35*1.0*1.2 |

10 | Container | 40GP*2 |

Layout drawing of machine

producing process:

install the steel coil on the un-coiler→Guiding→Warm box(heating)→ Roll-forming→PU Injection machine —→ roll forming →Warm box(white glue and black glue foaming) →Adjusting device → Punching device→ Flying saw cutting→Run out table

machine photo:

We can also customize the products according to customer ' s

requirements

Our Services

1. Installation and training:

a.If buyers visit our factory and check the machine, we will teach

you how to install and

use the

machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach

you to install and operate.

c.If buyer needs our technician to go to your local factory, please

arrange board and lodging and

other necessary

things.

2. After Service

a.One year guarantee for whole machine.

b.24 hours technical support by email or calling

c.If there is any problem found of the machine, we will repair it

for free in one year.

Company Profile

Hangzhou Bluesteel Machine Co.,Ltd

We are a manufacturer specialized in custom roll forming machinery.

With our advanced techniques and experienced staff members, we can

produce simple profiles as well as complex components with

precision tolerances. Most of our main production staff members

have about 10 years of experience, ensuring quality machinery and

high values for our customers.

Our products are widely used in steel structure Construction, like

roof and wall,and door or window,and supermarket ,warehouse etc.

Advantages of Roll Forming:

Roll formed parts can have a variety of shapes, angles and curves.

Many materials are suitable for our custom roll forming machines,

which allows us to provide components and parts with a wide variety

of plated, pre-painted and laminated materials to meet your roll

forming needs. We design products that best meet specific needs.

bluesteel Machine’s mission is to provide the highest quality products as a competitive

price, good in Quality, On-Time Deliveries, and Superlative

Customer Support.

bluesteel Machine has become a reliable bridge between overseas customers and

rollforming machines based on its riche professional experience in

marketing steel products and providing services. The company

persists in seeking global business partners, provides them solid

service and keeps stable and reliance business modules.