Add to Cart

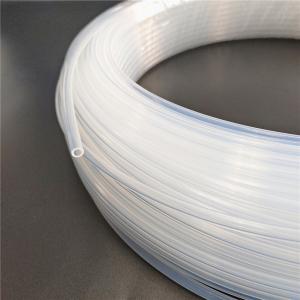

PVDF PTFE Pipe Hose Making Production Line ,PVDF PTFE Pipe Extrusion Machinery

Product Application

Aerospace transportation technology, electronics, components and

insulators, chemistry and pharmaceuticals, food processing,

environmental science, air sampling, fluid conveying equipment,

water treatment systems

1. Application: Teflong pipe extruder mainly produces: FEP, PFA,

ETFE and other fluoroplastic extrusion, Teflong (fluoroplastic)

high temperature resistance, wire, casing and other products

extrusion production, product specifications: external Diameter

1-25MM

Features of Teflong tube extruder: The Teflong tube extruder

produced by our company has mature and reliable technology, stable

production, and good product continuity. It has been verified by

continuous Teflong insulation sleeve manufacturers and the quality

of the equipment is trustworthy

Ptfe Tube High Temperature Pressure Heat Shrink Tube extrusion

machine HC276 material

high dielectric Fluoroplastic FEP PFA PVDF PTFE tube hollow bar

making machine line with HC276 extruder

Features:

1.Allow free assembling of the screw component, based on raw

material type. 2.Using the suitable die head for palletizing, such

as water ring cutting, under-water cutting and hot face cutting.

3.2High efficient force feeder ensures stable high capacity

material feeding, low power consumption. 4.Main screw has vacuum

exhaustion.

Ptfe Tube High Temperature Pressure Heat Shrink Tube extrusion

machine HC276 material

Ptfe Extruded Tube making line Flexible pipe extruder Braided Ptfe

Tube making machine

Fluoroplastic fep Ptfe pfa pvdf pipe making line Durable fep pfa

tube extrusion machine

Fluoroplastic fep Ptfe pfa pvdf pipe making line Durable fep pfa tube extrusion machine

| character | PTFE | FEP | PFA | PVDF |

| specific gracity | 2.13-2.22 | 2.12-2.17 | 2.12-2.17 | 1.76-1.78 |

| melting point(ºC) | 327 | 270 | 302-310 | 173-175 |

| maximum continous user temperature(ºC) | 260 | 200 | 260 | 150 |

| tensile strength(mpa) | 20-45 | 19-22 | 27-35 | 39-59 |

| coefficient of elongation(%) | 200-450 | 250-330 | 280-400 | 300-450 |

| dielectric constant 10^3HZ 10^6HZ | 2.1 2.1 | 2.1 2.1 | 2.1 2.1 | 7.72 6.43 |

| volume resistance(Ω-CM) | >10^18 | >10^18 | >10^18 | >10^14 |

| dielectric breakdown strength v/mil | 480 | 500-600 | 500 | 260 |

Process flow:

Raw material→Screw feeder → Parallel twin screw extruder →Hydraulic

filer exchanger→ Mould head →water tank→winder → Plastic standard

cutter→ Finished product packing.

Extruder composition:

1. Host machine : The screw and barrel of the host adopts new

Hastelloy C 276 steel, ceramic or cast copper heating products. The

speed of the host adopts energy-saving frequency conversion speed

control, intelligent temperature control meter temperature control,

and the main motor is driven by Siemens motor.

2. Machine head mould: new Hastelloy C 276 steel

3. 5m stainless steel vacuum sink: It can be adjusted in three

dimensions, front and back, left and right, up and down, easy to

operate, beautiful and practical appearance.

5 Belt traction machine: belt traction machine, 600MM effective

length, provide sufficient traction, servo motor drive, frequency

conversion speed regulation, precision transmission parts, the

traction speed is stable and no jitter.

6. Winding machine: No-disk winding, high-voltage motor control,

neat winding.

Why choose YAOAN MACHINERY?

1. Profession: YAOAN only make plastic extruder since 1980s,

extensive experience and professional team ensure our leading

position in plastic extruder industry.

2. Quality: The quality of products is footstone of enterprise's

constant development, always endeavoring to do still better,

quality comes first, developing & innovative is our

responsibilities;

3. Delivery: We optimize factory management, and improve production

flow so as to shorten production period for you in biggest extent;

4. Cost control: We do best to lower down production cost by our

inner management improvement, so as to ensure that our products are

competitive enough in market, and to realize higher

performance-price ratio of our products.

FAQ

Q1: What is the guarantee of the machine?

A1: The guarantee period of our machine is 12 months after the

machine is installed well in buyer's factory;

Q2: What package do you use for the machine?

A2: Painted the machine with anti-corrosion oil, and then covered

with plastic film, and then packed into wooden case or fixed onto

wooden pallet as per clients' requirements, or shall be loaded into

container with film packing. After fixed all machines, we will use

drying agent to keep container inside dry.

Q3: Do you have instruction manual to guide us if i buy the

machine?

A3: Yes, we supply detailed user manual for your reference. PLS

read it carefully for guide. If there is still problem which could

not be solved, PLS contact us, we are ready to help you anytime.

Q4: What is your service to overseas clients?

A4: We supply perfect overseas service. We shall send engineers to

overseas for machine installation and commissioning and test

production guide, and also training to the workers of the buyer.

And we are ready to give technical support anytime.