Add to Cart

High Precision Auto Injection Molding Machine Metal Stamping

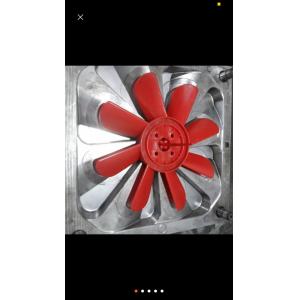

Plastic Fan Blade Injection Mould

Plastic fan blade injection mould Customized

Plastic injection insert molding is a plastic injection molding

process in which thermoplastic material is molded around an insert

piece or pieces placed in the plastic injection molding cavity,

resulting in a single strongly bonded, integrated assembly, with

the insert or inserts encapsulated by the plastic. Inserts can be

metal, another plastic, ceramic or just about any substance that

can withstand the plastic injection molding process.

Plastic injection insert molding is an effective alternative to

assemblies manufactured using soldering, adhesives or fasteners,

with benefits including:

High precision Customized Plastic injection mold

| Product name | High precision Customized Plastic injection mold |

| Mold shaping | Plastic Injection molding |

| Mold base | LKM;HASCO;DME,etc |

| Mold material | NAK20,S136,P20.718H,738H,45#,etc |

| Mold cavity | Single or Multi |

| Tolerance | +/-0.02mm |

| Finish | Anodized,Polish,Silk-screen,Painting,etc |

| Sprue gate | Hot/cold runner;pin-point gate,etc |

| Design software | UG,PROE,CAD,SOLIDWORK,etc |

| Product material | ABS,PP,PE,POM,PMMA,etc |

| Mold life | 100k-500k shots |

| Lead time | 25-45 days |

| Transportation | By sea, by air or by land as you request |

| Package | Standard or as you request |

| OEM/ODM | Acceptable |

| Certificate | ISO9001:1008,SGS, |

Plastic Mold (Mould) production process:

1. 3D drawing/Samples for quotation: According to 3D drawing or

samples for quotation.

2. Negotiations: Including the price of moulds, moulds sizes,

material for cores & cavities, weight of product, product

color, payment, moulds lifetime, delivery, etc.

3. Purchasing Order : After the customer confirming the mould

design and quotation.

4. Making mold(moulds): Confirm drawing, start to do DFM, mold

flows and mold detail agreed with the customer, start producion.

5. Production schedule: Every week we will feedback to the customer

about the mold progress(picture).

6. Sample shoot: We provide the moulds test samples for

confirmation(about 10-15 piece), we will start mass production when

get your signature samples.