Add to Cart

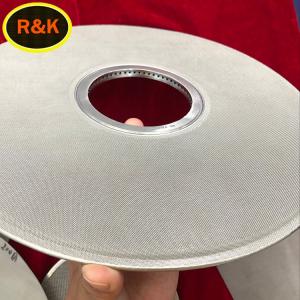

Round shape 316L 0.5 micron ultra fine stainless steel sintered

filter mesh

Product Description

Sintering and pressing can make each layer of stainless steel wire

mesh stick and fuse together, with high mechanical strength and

overall rigidity, and easy processing (cutting, stamping, bending,

welding).

Our main products include

Five-layer sintered mesh

Sintered mesh laminate

Sintered mesh with perforated metal

Sintered metal filter

Sintered metal filter disk

Folded sintered mesh filter

Sintered cone filter

Sintered metal fiber felt.

Product Feature

1.Surface filtration

2. Corrosion resistance

3. High temperature resistance

4. Filtering accuracy is stable

5. High strength and rigidity

6. The mesh is smooth

7. Easy to clean and can be used repeatedly.

8. Easy to shape, process and weld

Product usage

Stainless steel sintered mesh laminates are available in a wide

range of filtration grades for water treatment, liquid and gas

filtration, beverages, medical, chemical processing, food and

beverage, pharmaceutical and transportation industries.

Sintered mesh can be used for filtration of polymers, chemicals,

foods, hydraulic oils and fuels, pharmaceuticals and cosmetics,

water and emissions. It is also used for the fluidization of bulk

materials in gravity conveyors, trucks, conveyors, storage silos,

dryers, bulk materials and coolers.

Product Parameters

Note: This list for a reference, not for the complete list.

Nomin | structure prodextive layer+control layer | Thickness (mm) | air perm eabilit | Bubble pressure (mm) | weight (kg/m2) | porosity |

| 1 | 100+400*2800+100+12*64+64 | 1.7 | 1.81 | 360-600 | 5 layer 8.4 | 40% |

| 5 | 100+200*1400+100+12*64+64 | 1.7 | 2.42 | 260-550 | 6 layer 14.4 | 40% |

| 20 | 100+165*800+100+12*64+64* | 1.7 | 4.5 | 170-450 | 40% | |

| 200 | 40+80+40+20+40+80+40 | 2 | 26 | 50-150 | 40% |