Induction Heating Machine , Magnetic Induction Heater Tail Gas Heat Recycling System

Brand Name:xinlingyu

Minimum Order Quantity:1 set

Place of Origin:China

Contact Now

Add to Cart

Verified Supplier

Location:

Xuzhou Jiangsu China

Address:

Office:Room 1818, South building, No.66 Kunpeng road, Economy & Technology Development Zone, Xuzhou City, Jiangsu Province, China.

Supplier`s last login times:

within 1 hours

Product Details

Company Profile

Product Details

If the flux has only normal temperature, Zncl2 and HN4CL attachment will be slowly, and the flux is not easy to be dry on the working piece, resulting in the zinc explosion when the working pieces get into the zinc tank.

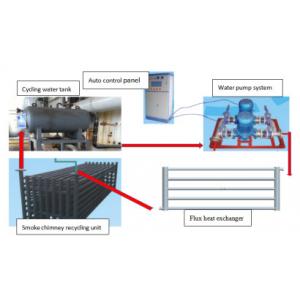

Burning tail gas heat recycling system without extra heating source, by heat exchanger to keep the temperature 60~70 °, the density of Zncl2, NH4CL reduced considerably, and also increased the uniformity of Zncl2, NH4CL attachment on the working piece, and the zinc layer will be more uniformly and good galvanization result.

Induction Heating Machine , Magnetic Induction Heater Tail Gas Heat Recycling System

Inquiry Cart

0