Add to Cart

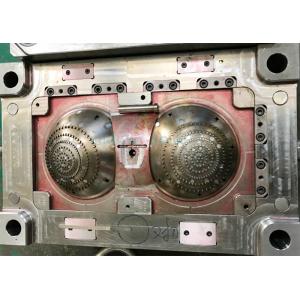

Custom Auto Head Lamp Plastic Auto Parts Mould Car Light Parts ,

Auto Parts Mold

Product Description:

| Material type: | Stardard steel |

| Cavity no.: | Single or Multi Cavities or Customized |

| Cav&Cor Material: | S136,SKD61,H13,718,P20 etc |

| Hardness of Cav&Cor: | HRC48-58° |

| Mould Base: | LKM&Hasco&DME standard |

| Surface finish: | SPI A-1,SPI A-2,EDM etc. |

| Mold components: | Mold base,core and cavity |

| Mold Gate: | Hot runner,direct sprue gate,side gate,pin-piont Gate etc |

| Runner system: | Hot or cold runner |

| Mould Life: | 500-3000K shots |

| Product material: | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

| Suitable for: | Plastic injection Parts |

| Design software: | CAD,UG,Pro E,Solidworks |

| Package | Wooden or Plywood Case |

| Delivery | 4Weeks |

| Value-added service: | Polish,texture,painting,screen printing,turnkey project |

| Export country: | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

Erbiwa Intro.

Offered Service:

Project Management flow:

| 1.R&D | We support customer R&D. Make the files or improve the design if you needed |

| ↓↓↓ | |

| 2.Quotation Making | Mould Quotation will be finished in 1 day according to information we get |

| ↓↓↓ | |

| 3.Negotiation | The quality ,price ,material, delivery time .payment item. ect |

| ↓↓↓ | |

| 4.Mould Design | 3-5 days for mould and product 3D/2D drawing design |

| ↓↓↓ | |

| 5.Mould | According to customers' request to build the mould.Before make the mould .we send mould design to customer approval first . Mould will be usually finished in 25-60 days |

| ↓↓↓ | |

| 6.Mould Testing | When moulds are finished,we will test the moulds to check it satified consumers' needs.And we will send samples for consumers' reference. |

| ↓↓↓ | |

| 7.Sample confirm | If the first sample come out is not satisfied customer .we modify the mould and until meet customers satisfactory |

| ↓↓↓ | |

| 8.Delivery | Delivery goods by sea or by air ,according customers requirement |

Company Intro:

Erbiwa has rich experience in custom tooling and injection molding, nowadays we have become one of the global famous mold makers in manufacturing large plastic injection molds.

With the modern business management system and ISO9001:2015 Quality System guideline, the sophisticated production techniques, the advanced manufacturing equipment, and our qualified and dedicated team, we are full of capabilities and have great confidence in offering you professional one-stop solution of mold designing, mold making, injection molding and beyond-value service.

We serve a broad range of customers in the field of Auto Parts. Erbiwa make over 200 molds per year, mainly of the molds and plastic parts are exported to America, Germany, France, Turkey, Italy and other countries worldwide. We have established long-term cooperation with our clients and are continually improve top quality molds and plastic parts to our clients, establishing close strategic partnership to keep customer's satisfaction and success, growing up together with customers.

Erbiwa Mould industry Co., Ltd is ready to become your most satisfied partner to support your growing business.

Service Scope:

Expert in Auto Parts, Household Appliance large plastic molds

Plastic parts injection

Prototype parts

Market Advantage:

Factory Capability:

20 molds per month (Max.)

Max.plastic part product size 1500x1500x1500mmmm, Max. mold weight

15 tons

The displayed pictures is only for your reference,we can make various kinds of auto plastic injection mold according to your requirements. Contact Erbiwa today and begin enjoying the benefits of high quality and low price products

The displayed pictures is only for your reference,we can make various kinds of auto plastic injection mold according to your requirements. Contact Erbiwa today and begin enjoying the benefits of high quality and low price products.