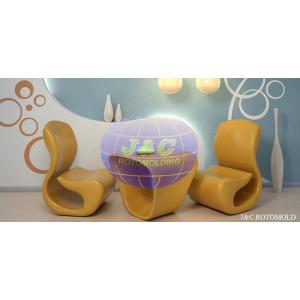

Precision Plastic Rotational Moulding For Rotomolded Chair / Sofa / Lounge / Tea Table

Add to Cart

customized designed for plastic rotomolded chair, sofa, lounge and

tea table

1. Rotational molding, including capital equipment (machinery,

processing equipment, etc.) is a cost effective option for plastic

manufacturing.

2. Rotationally molded parts are 100% stress-free, have excellent

impact resistance, and can withstand chemical and environmental

attack.

3. Value added features, such as threaded tank necks, inserts,

double walls, intricate contours, etc. can be produced via

rotomolding.

4. Speed-to-market advantage: once a design is finalized, tooling

can be produced in a manner of weeks, offering a distinct advantage

over other processes.

5. Rotational molding allows for the integration of multiple parts

into one piece, saving on manufacturing and assembly costs.

J&C SUPPLIES YOU WITH FREE DESIGN WORK OF ROTOMOLDING MOLD!

Complex figure processed by CNC machine. The design work takes very

long time. But we supply you with free work!

Aluminum A356 material. CNC processes the good quality aluminum die

casting part which confirms there is no porosity. Surface will be

very smooth.

Part lines are very small , around 0.1mm.

About Us

Shanghai Jiechuang Mold Manufacturing Co.,Ltd.Combined professional

experience in varied and demanding rotational molding applications,

exceeding customer's expectations both nationally and

internationally for over 10+ years.We will provide you with a true

one-stop shop for all of your product design, prototyping, tooling

and full-scale manufacturing needs.

CNC machines we have are all Hision Brand, which is the most famous

brand in China, which are more precise when process your aluminum

rotational molds.

J&C Rotomold Company is located in Shanghai, which is the

centra of commericial city , has convient transportation for you to

visit us at any time.

We offer significant differences compared to other molders

including:

· Project Management

· Design and Engineering

· Research and Development

· Rapid Prototyping

· In-house Cast Aluminum Tooling

· Rotational Molding (Rotocasting)

· Multi layer Part

· Molded-in Inserts

· Mold In Graphics

· In Mold Painting

· Secondary Operations

· Post Mold Finishing

· Light Assembly

· Mold On Graphics

· Post Mold Painting

· Product Testing

· Graphic Design and Layout

· Packaging and Shipping

| ||||||||||||||||

RFQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 35 days after confirming drawing and receive advanced payment.

Q: Do you provide samples once open mould?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 50% advanced payment, the balance before shippment.