Add to Cart

Products description:

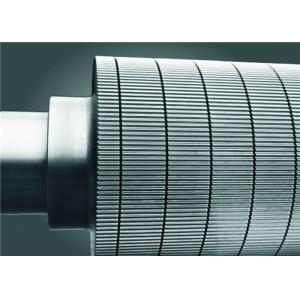

Hardness 55 to 60 CrMo Alloy Steel Corrugated Roller is Used for

carton box corrugator machine,single facer machine .

The upper and lower corruagted( corrugating, flute) roller for

single facer machine,Made of 48 CrMo alloy steel or tungsten

carbide with hard treatment by laser,the hardness is above

HRC58o-60o.The surface is well treated by grind and plated chrome.

Different type of flute according to user's request.

Corrugated Rollers Specification:

1.Material :Special 48CrMo alloy steel fine forgings

2.Hardness:>HRC58 Quenching layer depth :5-7mm

3.Coating Thickness 0.06and 0.07mm Tungsten Coating Thickness

4.Surface plating: Micro hardness HV900-1250

5.Combination hardness >75MPa

6.Visible optical porosity <1%

7.The optimization of economic type design

8.High-speed Corrugating Rolls :twice fine grinding

Corrugating Roll Flute Type

| Flute Type | Flute | Teeth/300mm | Height of Flute |

| A | UV | 30±2 | 4.6-4.9 |

| C | UV | 39±3 | 3.6-3.9 |

| CB | UV | 44±2 | 3.0-3.4 |

| B | UV | 50±2 | 2.6-2.9 |

| BE | UV | 66±3 | 1.9-2.1 |

| E | UV | 90±10 | 1.1-1.5 |

| F | UV | 124±10 | 0.7-0.8 |

| G | UV | 185±12 | 0.5-0.65 |

| N | UV | 200±15 | 0.4-0.5 |

| O | UV | 267 or design | 0.25-0.35 |

Corrugated Rollers Feature:

1.Employing advanced heat treatment and plating technology, as well

as high quality 48CrMo alloy steel forge piece,we can offer a wide

range of rolls featuring high precision ,high hardness and long

life.

2.It adopts computer assistant design,and sets allitems parameters

scientifically, soitinsures the quality specification

economical,reliable and reasonablel

3.It has big CNC corrugated roll precision grinding machine

group,and they all work for corrugated roll.l

4.Computer control to grind the concave rolll

5.Select the good quality of 48CrMo, 50CrMo alloy steel forge piece

Adopt Germany advanced process to quenchin super ficialinter

mediate frequency,hardened

layer>7mm,hardness>HRC58-60(HS73-80),the hardness uniform

with no soft zone.l

6.We adopt the most advanced high-efficiency

Atotech.Heef-25micro-cracks functional chrome plating technology

and equipment,to be morerigid,smoother,more light,more

wear-resistant surface hard chrome plating,electroplating longer

life than ordinary more than 25 percent.

7.We provide repair service for old corrugated roll at anytime

1.Packing : Use non-fumigation wooden box, it's convenient to

customs clearance.Could save customers more time.

2.Delivery Time:Shipped in 60days after payment

Inspection of corrugated roller before installation

(1) clean and check the corrugated surface appearance of corrugated roller (including the quality of surface plating).

(2) clean and check all fastening parts of connection (including internal and external threads).

(3) check the outer diameter and middle height of corrugated roll (the whole roll surface is divided into more than five measuring points from both ends to the middle).The middle and high detection points are odd, and the middle and high data should be symmetrical on both sides.Measure with the outside diameter micrometer of corresponding specification (outside diameter micrometer can be bought commonly by electromechanical company).

(4) check the corrugated roll height.Needle type depth dial meter measurement (needle type depth dial meter is not currently bought in China, must be imported.Or may use the ordinary depth dial gauge to change the system).

(5) clean and check the outer diameter and appearance of each shaft gear of corrugated roller, and measure the outer diameter with the micrometer of corresponding specifications.