Add to Cart

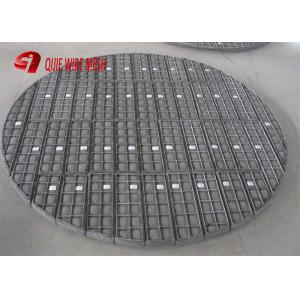

York 431,421,709 mesh demister pad for distillation column,drying

tower

wire mesh demister used for gas separation tower entrained droplets, to ensure that

the mass transfer efficiency, reduce the loss of valuable materials

and improving the tower after the operation of the compressor, more

commonly in the top screen defoaming device Settings. Can

effectively remove 3 - 5um droplets, tray if setting between

demister, not only can ensure the mass transfer efficiency of tray,

also can reduce the plate spacing. So the screen defoaming machine

is mainly used for gas liquid separation. Also for the air filter

used for gas separation. In addition, the screen also can be used

as instrument of buffer in instrument industry, in order to prevent

the radio interference of electromagnetic shielding, etc.

Type of wire mesh demister

| Type | Specification |

| Standard type | 40-100 60-150 105-300 140-400 160-400 200-570 |

| High-efficiency type | 60-100 80-100 80-150 90-150 150-300 200-400 300-600 |

| High-penetration type | 20-100 30-150 70-400 100-600 170-560 |

| Damping type | 33-30 38-40 20-40 26-40 30-40 30-50 48-50 30-60 30-80 50-120 |

The efficiency of the pad is a function of pad thickness, wire

diameter, closeness of weave, etc. The thickness of the pad is not

very critical since droplet coalescence is completed in the first

one or two inches and the extra thickness is mainly for catching

the re-entrained material. Thickness usually provided is between

100 mm and 300 mm.

A vane type demister consists of a number of parallel corrugated

plates. When gas passes between the plates it has to change

direction a number of times. The heavier particles are thrown out

and get collected in the pockets. Coalescence of small particles

into bigger particles is provided by agitation and surface contact.

The surface of the element is usually wet and particles striking it

are absorbed into the liquid film. The efficiency of the vane type

demister is a function of pressure drop since closer plates

introduce more pressure drop.

Style and Feature | |||||||||||

Style | Density kg/m3 | FreeVolume % | SurfaceArea m2/m3 | T.C.I | Equivalent To: | ||||||

York | Knitmesh | Vico-Tex | Koch | Metex | |||||||

H | 80 | 99.0 | 158 | D80 | 931 | 4536 | 160 | 511 | Hi-Thruput | ||

L | 120 | 98.5 | 210 | D120 | 422 | ||||||

N | 144 | 98.2 | 280 | D144 | 431 | 9030 | 280 | 911 | Nu-Stanadrd | ||

SN | 128 | 98.4 | 460 | D128 | 326 | 415 | 706 | ||||

SL | 193 | 97.5 | 375 | D193 | 421 | 9033 | 380 | 1211 | Xtra-Dense | ||

SM | 300 | 96.2 | 575 | D300 | |||||||

SH | 390 | 95.0 | 750 | D390 | |||||||

T | 220 | 97.2 | 905 | D220 | |||||||

R | 432 | 94.5 | 1780 | D432 | 333 | 800 | Multi-Strand | ||||

W | 220 | 97.2 | 428 | D220 | Wound | ||||||

GS | 160 | 96.7 | 5000 | D160 | 371 | ||||||

drawing of demister pad:4-Cell Demister Pads Drawings

6-Cell Demister Pads