Add to Cart

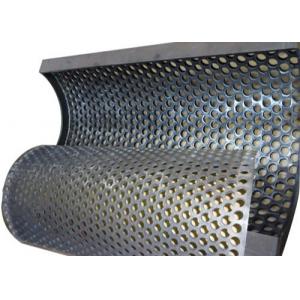

0.8mm Hole 80mm Width Stainless Steel 304 Sieve Bend Perforated Screen

Mainly used for liquid/solid separation.

Sieve Bend Screens because the Dutch State adapts sieve bend in

mine development first. Sieve bends are manufactured to suit a wide

range of industries such as Sugar, Coal Mining & Quarrying, Mineral Processing, Cement, and

Industrial & Urban Effluent Treatment etc. Sieve bend screens

are also used as a pre-filter in urban & industrial waste

treatment plants to improve the performance of the clarifier by

drastically reducing the load. Widely used for fiber removal in

Starch industry.

A sieve bend consists of a concave curved profile wire screen

mounted in a frame with the screen openings perpendicular to the

flow. A curved screen has greater capacity than a flat screen due

to forces exerted as material flows against the curved surface.

As slurry flows down the screen each wedgewire's sharp leading edge

slices away a thin layer of water and small-particle solids. Larger

particles continue down the screen surface, with much of the liquid

removed. Separation size is considerably smaller than screen

openings, usually about one half the opening size.

Sieve Bend Perforated Screen

Steel grade under GOST2176-77 (similar to ZGMn13-1, ZGMn13-1-4,

ZGMn13-2, ZGMn13-3);

Manganese steel;

Hardness: <220HB;

Diameter of bores: 40 mm;

Quantity of bores: 52;

Unpointed casting radius: 3-8 mm;

Weight: 30 kg;