Product Details

Marble Stone UPVC Window Making Machine Line New Type Double Screw

Extruder

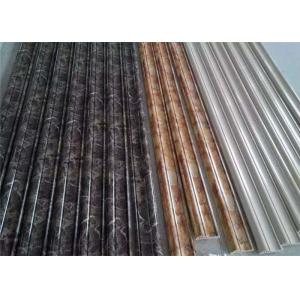

PVC imitation marble profile widely used for decorative,such as waist line, door window line, sunshade arc, stair lintel, publicity

column frame, frame lines, etc., can be used in high-grade hotels,

shopping malls, residential, villa, KTV etc. Building decoration.If

you're going to be hone or business place luxury building

decoration, imitation marble lines are good options.

Machine list :

1. Coincal Twin Screw Extruder:

Adopting specially screw designs according to different materials

make the high polymer micro-foam uniform plasticization, high

extrusion. Imported famous brands AC inverter makes the rotation

speed stable to ensure the main extruder and accessory machines

move synchronously

2. Profile moulds:

Material 3Cr17, it includes the die head parts, vacuum calibrator

parts, water cooling tank parts

3.Vacuum calibrating table:

Adopts powerful turbo cooling system, easy to achieve satisfactory

cooling effect. According to different moulds and different

customer requirements, the vacuum calibrating table can be optional

as 4m, 6m.

4. Hot stamping machine:

At least 9 sets

5. Haul off machine:

Adopts special lifting technology, and has the features of stable

running, reliable working, powerful hauling etc,

6. Cutting machine:

The moving speed of the cutting unit is synchronized with hauling

speed. Through prseting,the cutting unit is capable for automatic

cutting with fixed length. Dust recycling device is also equipped.

7. Other accessory machines:

High speed hot and cold mixer, plastic crusher, plastic pulverizer

The working process of PVC marble stone profile machine:

PVC powder + additives → mixer → screw feeder → extruder → mould →

vacuum forming table → hot stamping machine → haul-off and →

cutting machine → stacker → the final products.

Company Profile

COMPANY OVERVIEW

ZHANGJIAGANG LANGBO MACHINERY CO., LTD. is leading company offering quality machinery for a wide range of

plastic extrusion and recycling processes from China.

Due to our constant commitment to plastic extrusion and recycling

technology, we have emerged as a leading manufacturer of machinery

for PVC/PE/PP-R pipe, PE/PP-R composite multi-layer pipe, PVC

profile, PVC/PP/PE composite profile, PVC compounding and recycling

for PET/PP/PE and other wasted plastics.

Made of quality raw material and using world class technology, our

machines are widely appreciated for their salient attributes like

efficient and consistent performance, lower power consumption,

durability and corrosion resistance. With decades of valuable

industry experience, we can deliver quality machinery in both

standard and customized specifications.

In the fast-growing competitive market of plastic machinery, we

stand out as a growth oriented company that recognizes the needs of

the plastic manufacturing industry and provides comprehensive

services including machinery operation and maintenance instructions

because of we continuously keep an eye on innovation.

We have clientele in both domestic and international markets, and

we serve them with unconditional support. Our active research and

development enables us to deliver solutions for specific extrusion

and recycling needs of clients and scaling newer heights in the

plastic industry.

Our mission:

- To optimize our manufacturing capabilities and elevate our position

as a leading manufacturer plastic extrusion and recycling

machinery.

- To innovate excellent, functional and cost-effective plant for

multiple extrusion and recycling processes.

- To provide apt solution for every extrusion and recycling need.

Core Values:

- Constant development

- Need-oriented solution

- Undeterred commitment towards client's satisfaction

- Future readiness