Product Details

Mini Granulator Twin Screw Extruder Home Use Granulation Pp Pe

Making Machine

Mini granulator twin screw extruder home use granulation PP PE

making machine has excellent mixing performence, good self-cleaning

performance and flexible modular configuration characteristics

which make them suitable for processing different types of

material. they are

extensively used in the polymers processing, food staff processing

and chemical produts, especially for various of high malecular

materials.

Mini lab testing machine Twin Screw Extruder Pelletizing Line with

PP PE color masterbatch 3~5kg/hhas many different kinds of machine,all

of which just according to our customers' needs.

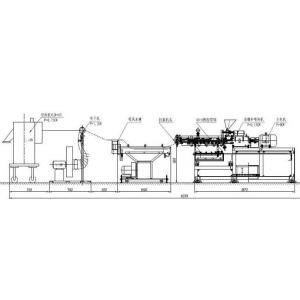

Machine Composition

| Model | Machine | Qty |

| 1. | GSD16 Lab Single Screw Extruder | 1 set |

| 2. | Electric Control System | 1 set |

| 3. | Water Strand Cutting System | 1 set |

In most cases, twin screw extruder for compound materials is used

as mixing equipments in processing high molecular materials, the

modification

process and master batch preparation of polyolefin materials and

engineering plastics require sufficient and intensive mixing, which

differs

depending on material systems. Key factors determining the success

and efficiency of mixing:

- Excellent equipment performance

- Reasonable mixing process

- Advanced combination technique

- Rich processing experience

Machine Details

1. GSD16 Lab Single Screw Extruder

Gear box

------Speed reducing system combine with torque distributing system

together, high torque

------Speed rate:16:1

------Gear: high speed heavy load hard surface, gear axle material

is 20CrNi2MOA, HRC58-62;

------Lubricant oil cooling system: oil pump motor 0.75kw

2. Electric Control System

------50/60HZ 220/380/480 V 3P OR CUSTOM POWER

------ AC contactor :SIEMENC brand

------Main motor air switch: LG brand

----- Intermediate relay: SIEMENS brand

-----Temperature controller: OMRON brand

3. Water Strand auxiliary system

-----Water tank: S/S, length:0.5 meters.

-----Dryer: one set

-----Pelletizer: one set Power:0.35 kw

Company Profile

COMPANY OVERVIEW

ZHANGJIAGANG LANGBO MACHINERY CO., LTD. is leading company offering quality machinery for a wide range of

plastic extrusion and recycling processes from China.

Due to our constant commitment to plastic extrusion and recycling

technology, we have emerged as a leading manufacturer of machinery

for PVC/PE/PP-R pipe, PE/PP-R composite multi-layer pipe, PVC

profile, PVC/PP/PE composite profile, PVC compounding and recycling

for PET/PP/PE and other wasted plastics.

Made of quality raw material and using world class technology, our

machines are widely appreciated for their salient attributes like

efficient and consistent performance, lower power consumption,

durability and corrosion resistance. With decades of valuable

industry experience, we can deliver quality machinery in both

standard and customized specifications.

In the fast-growing competitive market of plastic machinery, we

stand out as a growth oriented company that recognizes the needs of

the plastic manufacturing industry and provides comprehensive

services including machinery operation and maintenance instructions

because of we continuously keep an eye on innovation.

We have clientele in both domestic and international markets, and

we serve them with unconditional support. Our active research and

development enables us to deliver solutions for specific extrusion

and recycling needs of clients and scaling newer heights in the

plastic industry.

Our mission:

- To optimize our manufacturing capabilities and elevate our position

as a leading manufacturer plastic extrusion and recycling

machinery.

- To innovate excellent, functional and cost-effective plant for

multiple extrusion and recycling processes.

- To provide apt solution for every extrusion and recycling need.

Core Values:

- Constant development

- Need-oriented solution

- Undeterred commitment towards client's satisfaction

- Future readiness