Product Details

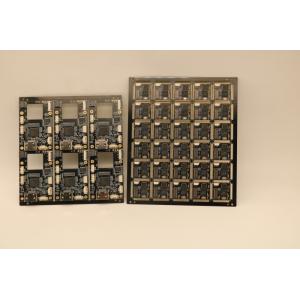

EMS manufacturer PCB Assembly SMT PCB Assembly Electronic

Manufacturing Service

1. More Pictures

How to find a good EMS manufacturer:

Finding a good EMS (Electronic Manufacturing Services) manufacturer

is crucial for the success of your electronic product. Here are

some steps to help you find a reliable EMS manufacturer:

- Determine your requirements: Clearly define your project

requirements, including the type of electronic product you want to

manufacture, the desired production volume, quality standards,

budget, and any specific certifications or regulatory compliance

needed.

- Conduct market research: Look for EMS manufacturers that specialize

in your product category or have experience with similar projects.

Use online directories, trade shows, industry publications, and

referrals to create a list of potential manufacturers.

- Assess their capabilities: Evaluate the capabilities and resources

of each EMS manufacturer on your list. Consider factors such as

their production capacity, equipment quality and maintenance,

technical expertise, quality control processes, supply chain

management, and their ability to scale production as your business

grows.

- Quality standards and certifications: Verify if the EMS

manufacturer follows industry-standard quality management systems

like ISO 9001. Depending on your product requirements, look for

additional certifications such as ISO 13485 (medical devices),

ISO/TS 16949 (automotive industry), or certifications specific to

your industry.

- Request for proposal (RFP): Prepare a detailed request for proposal

that outlines your project requirements, including technical

specifications, quantities, delivery schedules, and any other

relevant information. Send the RFP to the shortlisted EMS

manufacturers and ask for a comprehensive proposal.

- Evaluate the proposals: Review the proposals received from EMS

manufacturers. Assess their responsiveness, understanding of your

requirements, proposed manufacturing processes, estimated costs,

and timelines. Pay attention to any value-added services they

offer, such as design support, prototyping, testing, or after-sales

support.

- Site visits and audits: Select a few EMS manufacturers that best

meet your requirements and arrange site visits to their facilities.

Observe their manufacturing processes, inspect their equipment,

evaluate their quality control procedures, and meet with their team

members. Consider conducting audits to assess their financial

stability, ethical practices, and overall business reliability.

- Client references: Ask the shortlisted EMS manufacturers for client

references. Contact their previous or current clients to gain

insights into their experiences, satisfaction levels, and any

issues they faced. This can provide valuable information about the

manufacturer's reputation and customer service.

- Consider logistics and location: Evaluate the manufacturer's

proximity to your location, as it can affect communication,

shipping costs, lead times, and overall supply chain efficiency.

Additionally, consider the manufacturer's ability to handle

international shipping if your production requires it.

- Negotiate and sign agreements: Once you have selected an EMS

manufacturer, negotiate the terms, including pricing, payment

terms, intellectual property protection, confidentiality

agreements, and any other relevant legal aspects. Have a clear and

comprehensive contract in place before proceeding with production.