Add to Cart

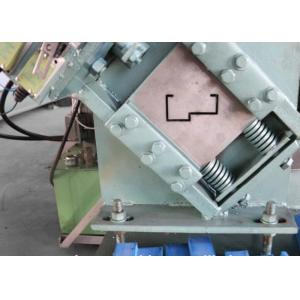

Shutter Door Bottom Rail Panel Cold Roll Forming Machinery Full Automatic

Shutter door slat roll forming machine there are serval types: European style shutter door machine, Australia style shutter door machine, shutter door with big holes, shutter door with perforation holes machine, shutter door U stud forming machine and others. No matter which type is made by the following process:decoiler→ sutomatic punching →feeder guide →roll forming→ flying cutting saw →run out table.

Product Technical Parameter

A. Manual Decoiler

(1) Max Width: 1250mm

(2) Inner Diameter: 500mm

(3) Outer Diameter: 1200mm

(4) Max Weight Capacity: 5T

B. Roll Forming

(1) Raw Material: Colored steel or galvanized steel

(2) Material Thickness: 0.5-1.2mm

(3) Working Speed: 12-15m/min; Adjustable

(4) Rollers: 20 rollers ( based on drawing )

(5) Material for Rollers: GCr15, polished, heated, quenched HRC55-60°

(6) Motor Power: 7.5KW

(7) Roller Diameter: 76mm

(8) Machine Side Plate Type: Guide Pin Type

(9) Transmission Type: Chain Transmission

(10) Finished Sheet Product as Stipulation: GB/T 12755-91

C. Hydraulic Cutting

(1) Cutting Type: Hydraulic, automatic cutting

(2) Blade Material: Cr12 with polished, heated, quenched HRC 60-62

(3) Power: 3KW

D. Control System

(1) Electrical Control: PLC Frequency Control System with touch screen

(2) Voltage: 380V/3Ph/50Hz(or as your local standard)

(3) Length Error: ±1mm

E. Output Table

(1) It is simple and used to load finished product

(2) Length: 4m

Technical Parameter

| Name | Description |

| Suitable Plate Material | Galvanized steel or color steel |

| Working Speed | 12-15 meters / min |

| Forming Steps | 18 stations |

| Driven system | gear box drive |

| Material of Roller | Gcr15, Quench HRC58-62 Plated Chrome |

| Material of Shaft | 45# Advanced Steel (Diameter: 76mm), thermal refining |

| Main Powe | 7.5KW |

| Cutting | Hydraulic Cutting Cr12mov |

| Material of Cutting Knife | Cr12Mov, Quench HRC58-62 |

| Hydraulic Station Power | 4KW |

| Touch Screen | Siemens Japan |

| Encoder | Omron Japan |

| Electric parts | Schneider |

Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting – product to run out table

Final Products Shows

Our Services

A . Free technical support and free accessories supply.

B. Engineer available to service machinery overseas.

C . One year warranty is provided.

D . Long life technical guidance for free.

E . We always offer technical support, quick response, all your inquire will be replied in 24 hours.