Add to Cart

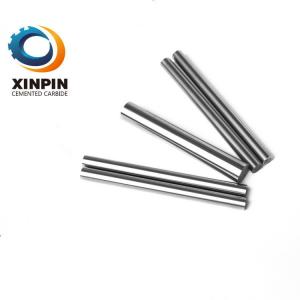

ISO9001:2015 tungsten carbide bar for end mills and solid carbide tools

Product description

Product specification

Specification: Diameter:1.5 mm x 330mm

Surface Condition: Sintered blank

Chemical Composition: WC :88.5% + Co: 6% + Others: 1.5%

Density: 14.8~15.0 g/cm3

Hardness: HRA90.5-91.5.

T.R.S.: 2200N/mm2

Recommended Grade: YG6, YG8, YG6X, YG012, YG013, YG8A etc.

Surface: stock in blank, center less blank and polished form.

Feature: Easy operation, long lifetime.

Company Introduction

Zhuzhou Xinpin Carbide Co.,Ltd. is a professional manufacturer of

high quality tungsten carbide for wood working industry. Our team

consists of engineers with over 20 year's experience of

production,technology, and research as well as marketing.

We always insist on purchasing high quality raw matrials ,

introducing the advanced production and testing equipment from home

and abroad, adopting advanced production technology in order to

guarantee an excellent quality for every piece of products

delivered to customers.

Today our company can provide a wide variety of products ranging

from saw tips,strips, and rods to other custom-made special parts

for customers from domestic and overseas.

To be your reliable business partner, we always aim to the strict

standards, the quality-first principles and the superior service to

meet your demands.

Grade Chart

| Grade | Density(g/Cm3) | Hardness(HRA) | T.R.S(N/mm2) | Recommended Cutting Applications | Proposal for welding |

| XF6 | 14.7-14.9 | 92.0-92.8 | ≥2600 | For solidwood,hardwood and composite board,etc. | Recommend the high-frequency welding |

| XF8 | 14.5-14.7 | 91.0-92.0 | ≥2800 | For construction formwork, Non-Ferrous Metal and various woodworking tools,etc. | Recommend the high-frequency welding |

| XF10 | 14.3-14.5 | 90.5-91.5 | ≥3000 | For solidwood,hardwood and various woodworking tools,etc. | Recommend the high-frequency welding |

| XK10 | 14.8-15.0 | 90.5-91.0 | ≥2400 | For solidwood,hardwood,etc. | Use resistance welding,and the temperature should be not too high |

| XK20 | 14.6-14.8 | 89.5-90.5 | ≥2600 | For softwood,solidwood,etc. | Use resistance welding,and the temperature should be not too high |

| YG11C | 14.3-14.5 | 87.0-88.0 | ≥2600 | For marble,granite and various mining tools,etc. | Recommend the high-frequency welding |

| SM07 | 14.8-15.0 | 93.2-93.6 | ≥3000 | For solidwood,hardwood,copper,aluminum,plywood,etc. | Recommend the high-frequency welding |

| SM10 | 14.2-14.4 | 91.5-92.0 | ≥3000 | For hardwood,Non-Ferrous Metal,PCB circuit board and various woodworking tools,etc. | Recommend the high-frequency welding |

Product application

Tungsten carbide rod grades are mostly fine and ultra fine grain with high performance. It's suitable for processing of non-ferrous metal, plastic materials, carbon fiber, chilled cast iron and heat-resistant alloy steel, high-temperature alloy steel, stainless steel, high manganese steel, etc. It can manufacture of drill bits, end mills, and reamers. Tungsten carbide bushing widely used in stamping tools and wear-resistant tools, etc.

Product feature

1. Long lifetime

2. High hard wear resistance

3. Easy operation

4. Stable quality performance

5. Corrosion resistance

Products photo

Ralated Products

Photo for certification and customer feedback

Product Packing

FAQ

1.Are you trading company or manufacturer?

we are factory.

2.What is your terms of payment?

Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%T/T

in advance, balance before delivery.

3.Can I get a sample before order if it is customized products?

Yes,we will send customized samples to confirm first, mass

production is only started by customer's approval.

4.Do you have stock for standard sizes?

Most of standard sizes we have in stock. You can check with our

sales manager.

5.I just have a sample,can you produce it for me?

Yes, we will much appreciate if you have the drawing and know the

material or application. If not, it doesn't matter, send us the

sample. We will check the material, make the drawing and produce it

for you.

6.Can I get a free sample?

We can offer a standard sizes sample below 50g. The over weight

need charge the cost. And we do not pay transport cost.

7.What kind of transportation can we use?

By air,by ocean,by express,by train. Whatever, any kind of

transportation can be choose.

8.Hong long will you need for production?

Usually, we need 15 to 35 days. For mass production, maybe 45 days.

9.Can you make stickers with our logo or laser logo on our

products?

Yes,we can.

For further information, don't hesitate to contact us.