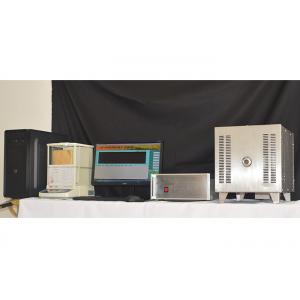

Description:

Its main use is to measure the gas performance of casting molding

sand, clay sand, resin sand, coated sand

and coating material in high temperature.

The highly intelligent computer gas-generating tester is the latest

computer-controlled high-intelligent plastic material analysis and

testing instrument in the testing instrument industry. It applies

advanced microelectronics technology, computer technology and

sensing technology to the detection of material gas evolution and

gas emission. Based on the principle of gas pressure measurement,

the automatic measurement of technical parameters of gas evolution

is realized. The whole process of gas evolution is displayed by

computer in time, and the results of analysis are plotted and

printed. This instrument is very simple and convenient to operate,

and is an indispensable instrument and equipment for modern foundry

laboratory.

main specifications

measuring range 0-200ml, accuracy: ±1.5%

temperature of pyrolysis furnace 600-1200℃, accuracy:±1℃

temperature of measurement system 0-120℃, accuracy:±1℃

temperature of working condition -5-45℃

humidity of working condition ≦85%

timing range 120min, can be set up arbitrarily

rated power 4KW

power source AC220V/50HZ

| measuring range | 0-200ml, accuracy: ±1.5% |

| temperature of pyrolysis furnace | 600-1200℃, accuracy:±1℃ |

| temperature of measurement system | 0-120℃, accuracy:±1℃ |

| temperature of working condition | -5-45℃ |

| humidity of working condition | ≦85% |

| timing range | 120min, can be set up arbitrarily |

| rated power | 4KW |

| power source | AC220V/50HZ |

Instrument features

1. The detection and circuit processing system has reasonable

design, strong anti-interference ability, stable display data,

accurate and reliable analysis results.

2. Grade PC computer WINDOWS XP platform color operating system,

screen display and printing are using Chinese or English

characters, keyboard and mouse, and LCD color screen, clear

interface, clear prompts. The operation is simple and convenient.

The analysis process dynamically displays and records various

real-time data, gas release curve, gas release time, test

temperature and so on. The functions of data and curve storage,

query and reproduction, printing and so on are convenient for

scientific research.

3. The electronic balance weighed with no quantitative to improve

the measurement accuracy and speed of analysis and test. It can

automatically collect the number saws and manually input arbitrary

selection.

4. The gas generating tester can automatically measure and display

the ambient temperature, furnace temperature and pressure measuring

end temperature, and use computer technology and automatic

temperature compensation technology to automatically control the

high temperature decomposition furnace and pressure measuring

system respectively. The analysis results are stable and reliable.

5. The pressure sensor manufactured by American SM company can

collect and process the gas volume at room temperature and high

temperature, and the data is stable and reliable.

6. The temperature of the measuring system can be controlled stably

at 105 C by constant temperature control. Without the influence of

water condensation and other factors on gasification, the

measurement results are more accurate and true.

7. All the data collected by this gas generating tester can still

be completely and unrestrictedly stored in the database of computer

operating system for query, display and print out. The system has

strong function, low failure rate and wide application range.

Computer can be used offline

main applications

It is widely used in foundry, machinery, casting, qualitative

inspection, scientific research, university lab....