Add to Cart

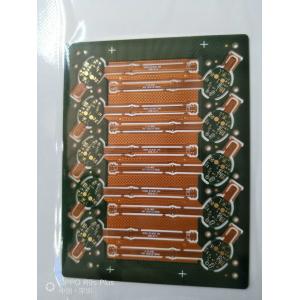

2-30 Layers Rigid Flex PCB FR4 / Polyimide Material ENIG Hasl OSP

Surface Finish,rigid flex circuit boards,rigid flexpcb

Our Services

We are a Manufacturer & Supplier Specializing in Double Side

PCB, Multi-Layer PCB, F4BK PCB, Ceramic PCB, Rogers PCB, Aluminum

PCB. Meanwhile, we provide PCBA ( Assembly) and ODM, OEM service.

We are specializes in a full SMT and through hole PCBA assembly,

obtaining components, building prototype quantities, and testing.

High quality,good price and service.

Our capability

PCB, FPC product application field

Various digital products, automotive new energy, automotive

products, military, aerospace, medical, wireless terminals, wired

terminals, communication equipment, communication stations,

finance, industrial industrial control, consumer electronics,

educational equipment, smart devices, smart products, security,

LED, computer, mobile phone and other electronic products

Detailed Specification of Flexible PCB Manufacturing

| Technical Specification | ||

| Layers: | 1~10 (flex Pcb) and 2~8 (rigid flex) | |

| Min Panel Size: | 5mm x 8mm | |

| Max Panel Size: | 250 x 520mm | |

| Min Finished board thickness: | 0.05mm (1 sided inclusive copper) | |

| Max Finished board thickness: | 0.3mm (2 sided inclusive copper) | |

| Finished board thickness tolerance: | ±0.02~0.03mm | |

| Material: | Kapton, Polyimide, PET | |

| Base copper thickness (RA or ED): | 1/3 oz, 1/2 oz, 1oz, 2oz | |

| Base PI thickness: | 0.5mil, 0.7mil, 0.8mil, 1mil, 2mil | |

| Stiffner: | Polyimide, PET, FR4, SUS | |

| Min Finished hole diameter: | Φ 0.15mm | |

| Max Finished hole diameter: | Φ 6.30mm | |

| Finished hole diameter tolerance (PTH): | ±2 mil ( ±0.050mm) | |

| Finished hole diameter tolerance (NPTH): | ±1 mil ( ±0.025mm) | |

| Min width/spacing (1/3oz): | 0.05mm/0.06mm | |

| Min width/spacing (1/2oz): | 0.06mm/0.07mm | |

| Min width/spacing (1oz): | Single layer: 0.07mm/0.08mm | |

| Double layer: 0.08mm/0.09mm | ||

| Aspect Ratio | 6:01 | 8:01 |

| Base Copper | 1/3Oz--2Oz | 3 Oz for Prototype |

| Size Tolerance | Conductor Width:±10% | W ≤0.5mm |

| Hole Size: ±0.05mm | H ≤1.5mm | |

| Hole Registration: ±0.050mm | ||

| Outline Tolerance:±0.075mm | L ≤50mm | |

| Surface Treatment | ENIG: 0.025um - 3um | |

| OSP: | ||

| Immersion Tin: 0.04-1.5um | ||

| Dielectric Strength | AC500V | |

| Solder Float | 288℃/10s | IPC Standard |

| Peeling Strength | 1.0kgf/cm | IPC-TM-650 |

| Flammability | 94V-O | UL94 |

Quotation Requirement :

1) Following specifications are needed for quotation:

a) Base material

b) Board thickness:

c) Copper thickness

d) Surface treatment:

e) color of solder mask and silkscreen:

f) Quantity

Shiping method:

1) By DHL, Fedex, UPS, TNT etc.

2) By sea if it is possible

3) By air

Surface treatment:

full board OSP, full board immersion gold, whole board electric

nickel gold, electric gold + immersion gold, electric gold + OSP,

OSP + immersion gold, OSP + carbon bridge, gold finger, OSP + gold

finger, immersion gold + gold finger, Shen tin, immersion silver,

lead-free tin spray

FAQ:

Q: What files do you use in PCB fabrication?

A: Gerber or Eagle, BOM listing, X, Y sitting report, PNP and

Components Position

Q: Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test

procedure?

A: Within 6-48hours for PCB quotation and around 24-48 hours for

PCBA quotation.

Q: According to the difficulty of high-layer boards, How can I know

the process of my PCB production?

A: 7-35days for PCB production and components purchasing, and

14-20days for PCB assembly and Testing

Q: How can I make sure the quality of my PCB?

A: We ensure that each piece of PCB, PCBA products work well before

shipping. We'll test all of them according to your test procedure.