Q235B Structural Steel Beams And Columns Fabrication H Section steel

Add to Cart

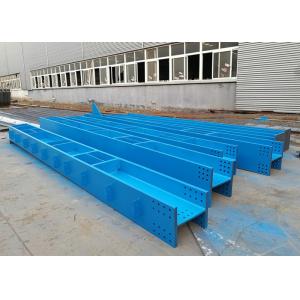

Structural Steel H Beam Fabrication H-Section Steel Structural Steel Beams And Columns

H-section steel is a kind of sectional area allocation more optimized, stronger weight ratio more reasonable economic section efficient profile, because its section and English letter "H" the same name.Because each part of H-beam is arranged at right angles, H-beam in all directions has the advantages of strong bending ability, simple construction, cost saving and light weight structure, has been widely used.

We have three steel structure production lines, equipped the flame

cutting machine, H-Section steel assembly machine, gantry welding

machine and shot-blasting machine, paint spray booth. We also put

apart the space for the fabrication of heavy-duty and large

structure steel components in our workshop.

| Products Name | Structural Steel H Beam Fabrication H-Section Steel Structural Steel Beams And Columns |

| Grade | Q235B,SS400,Q345B,S235JR,S275JR,ASTM-A36 |

| Size | 100x100mm-1500x1500mm |

| Thickness | 8mm-100mm |

| Length | 2-20meters |

| Shape | H-shaped column |

| Delivery Time | 7-15 Days if in stock size, or it will be 20-40 for customized |

| Payment Term | L/C or T/T |

| Package | By bundle or as customer's requirement |

| Application | Engineering or project, plant and equipment, mechanical equipment, bridge, etc |

| Surface | Black, coating, galavnized |

| MOQ | 30Ton |

1. Structural steel fabrication, painting , galvanizing ,

pre-assembly

2. Designing, fabrication and installation for Prefabricated steel

structure building.

3. Deepen or design the fabrication drawing or shop drawing based

on your architectural drawing and construction drawing

4. Engineering consulting service

QC/Technical Support

Raw material quality control

Thickness tolerance <0.25mm

Yield and tension strength testing in-house

Third party inspection certificate

Supply traceable mill certificate

Structural steel fabrication quality control

100% testing dimension tolerance <1mm

20% sample welding line ultrasonic testing, no fault, full

penetration.

20% magnetic powder testing, no bubble, no defect, Smooth and Full

Supply third-party inspection assistance.

Shot blasting and painting quality control

Shot blasting grade Sa. 2.5 Metal luster, no rust, no oil dirt, no

welding spatter, Roughness >75um

Paint primer within 5 hours after shot blasting, Holiday-free

coatings, smooth, No dust, Dry Film Thickness (DFT) >75UM

Pre-assembly testing the connection details.

1. Professional design team, we could design the drawing as your

requirement or calculate the steel quantity based on your drawing.

2. Skilled fabrication team and advanced equipment. We make the

independent production schedule to each project.

3. One-stop service: We have completed lots such kinds of projects,

we could provide the integrated proposal for your project.

4. Professional QC team will guarantee that we will provide the

production and service as your request.

5. After sales service: If it has any questions that need us to do

in your process of using, such as the maintain of outside

insulation and steel components, just tell us , we will try to

provide the service as well as we can.