Add to Cart

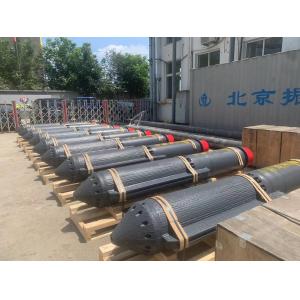

China 180 kW 426 mm vibroflot equipment pile driver for ground improvement applied in Middle East

History for vibroflotation in China

1. Vibroflotation was both in German in 1930s , then was developed to Europe,Japan etc. Vibro-compaction was first applied, vibro-replacement stone column was begin from 1970s.

2. Vibroflotation begin in China from the Tang Shan Earthquake in

1976, the grade of eathquake is 7.8.

In 1977, Beijing Survey and Design Institute researched Chinese

first vibrator of 30kW, this vibrator applied the first

vibroflotation project in Beijing Guanting Reservoir.

3. In 1982 year,Powerchina vibroflotation company researched 75kW vibrator,widely used in upstream and downstream cofferdam project of the Three Gorges in 1997.

4. Beijing Vibroflotation Engineering Machinery Co., Ltd (BVEM) was establish in 2007, the company comes from the equipment department of Power china vibroflotation company. Company vision : Outperform to Serve Vibroflotation

The company has: research and development department, manufacturing department, technology department, business department and construction department, etc, also has a large-scale intelligent production line for electrical vibroflot equipment.

Typical vibroflotation project cases

1. Chinese first vibrator 30kW applied in Beijing Guanting resevior Dam foundation reinforcement

2. 75kW vibrator applied in Three Gorges cofferdam

3. 180kW vibro applied in the thrid runway of HongKong airport

4. 260kW applied in many Islands in UAE and KSA

5. 225kW inverter vibrator applied in Hydropower Station in Sichuan

6. Also in other Hydropower station project, 220kW vibrator drive pile depth of 71.63 meter

7. Bottom feed vibrator applied in Hong Kong Zhuhai Macao Bridge Hong Kong Port

8. Bottom feed vibrator barge type applid in Dila Bay port in Timor Leste

Vibroflot compaction method

Under the effect of vibration, the saturated sand soil liquefaction

happen,which make the sand particles re-arranged and the soil

interspace reduced.

Boring

By vibration and the flushing of water and/or air, the vibroflot

penetrates to the designed depth.

Compaction

Compact the soil section by section up to the gound according to

the requirements of the compaction current, compaction time and

sectional compaction length.

The method is applied to sandy soil foundation with clay content not exceeding 10%,such as coarse sand, medium coarse sand, gravelly medium coarse sand. Usually the relative density can be increased to over 80% after vibro-compaction.

Vibro-replacement stone column method

Jet water and vibrate by vibroflot to form holes. Fill in pile

holes by section with solid filling materials such as gravel

(cobble) etc., to finally form composited foundation.

Boring

By vibration and the flushing of water and/or air, the vibroflot

penetrates to the designed depth.

Backfill

Fill stones into the bore-hole, and compact section by section up

to the ground according to the requirements of compaction current

and the sectional compaction length.

Vibro-replacement stone column method is applied to cohesive soil, soft clay, silty soil, and other soil types, after improvement, the bearing capacity can be improved to 200kPa-400kPa.