Product Details

PVC Vinyl Floor Tile Making Machine Spc Flooring Machinery Cutting

Machine

Main Features

The latest gerneration SJSZ92/188 SPC one step flooring extrusion

line/rigid vinyl plank production line/making machine:

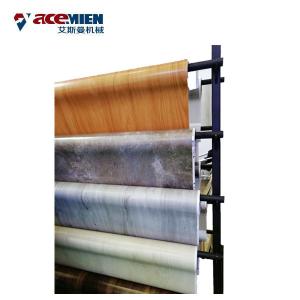

One step extrusion with online decoration film

laminate,wear-resisting layer at top and bottom with sound

insulation cushion layer.

a. surface can be laminatedwith different design decoration film;

b. laminate wear-resisting layer at top surface;

c. emboss with different design;

d. sound insulation cushion layer(optional)can be laminated at

bottom side.

It has the characteristics of zero formaldehyde, anti-mold,

moisture-proof, fire-proof, anti-insect, simple installation and so

on.

finished floor width:970mm or 1220mm,thikness:2-8mm;

raw material:PVC/CACO3/addtive;

max capacity:800kgs/hour;

average power:120kw

The SPC vinyl flooring plank/SPC flooring board/pvc flooring

tile/pvc flooring plank/luxury vinyl plank flooring /waterproof

vinyl plank flooring/interlockng pvc floor tile covering produced

by SPC flooring vinyl plank extruder SPC floor board making machine

is widely used in many different lines for various application

including:Department

Store,Hotel,Hospital,Restaurant,Bank,Office,Residence

SPC floor tile extrusion machine

| Product Name | Multi-Layer SPC Flooring Making Machine/LVT Vinyl Plank Floor

Production Line |

| Place of Origin | Jiangsu,China |

| Brand Name | Acemien |

| Certification | ISO9001-2000;CE |

| Minimum Order Quantity | 1set |

| Advantages | 1)Safety and environmental protection; 2)Waterproof and skid resistance; 3)Wear-resistance, corrosion resistance; 4) Luxing and beauty; 5)Installation convenience. |

| Applications | It's widely used in bedrooms, halls, kitchens and toilets; office

buildings, libraties, museums, shopping malls, restaurants,

factories, schools, hospitals and other ground pavement. |

| Product Structure | 1)UV Coating; 2)Wear Layer; 3)Printing Layer; 4)Middle Layer; 5)Base Layer. |

| Packaging Details | Standard exporting package |

| Delivery Time | 45 days after perpayment |

| Payment Terms | TT/LC |

| Supply Ability | 10 sets/month |

Company Profile

JiangSu Acemien Machinery Co., Ltd. is a brand production

enterprise which is the first batch of PVC roofing building

materials equipment, PP hollow construction formwork production

line in China, which focuses on plastic extrusion equipment and

plastic recycling equipment. The company has gathered a number of

outstanding talents and formed a high quality scientific research

team with the elite of Chinese and young science and technology as

the backbone. It has accumulated rich experience in product design

and profound theoretical knowledge in the continuous product

research and development practice.

Our company concentrate on five series equipment, they are

Synthetic resin tile and PVC corrugated tile extrusion equipment;

PP hollow construction formwork production line; Artificial marble

sheet and profile extrusion equipment; Post recycling and

granulation equipment; Conventional extrusion equipment such as

pipe/profile/sheet; Auxiliary equipment such as

mixer/crusher/pulverizer.

JiangSu Acemien Machinery has become a large-scale and modern

national enterprise in the plastic roofing and building materials

industry. The company insists on the business philosophy of

"professionalism, integrity, win win and development", and

continuously improves technology strength and supporting

capabilities. In the era of Internet +, we will keep pace with the

times.