Add to Cart

SMT Machine Parts Stainless Steel Pine Mesh Monorail Condenser Wave Soldering Flux Exhaust Filter

Introduce

The wave soldering exhaust filter is a key component used in wave soldering equipment. It is mainly used to filter the smoke and gas generated during the welding process to ensure the cleanliness of the production environment and the health of employees.

Wave soldering filters are used in exhaust boxes, condensers, evaporators, wave soldering spray filtration, and isolation of flux rosin and other residues. This stainless steel filter is mainly used in equipment such as wave soldering reflow chillers.The filter mesh is made of stainless steel and can be used after repeated cleaning

Specifications

| Material | Stainless steel |

| use | air filtration |

| Weaving style | Twill/plain weave |

| Monofilament diameter | 1(mm) |

| porosity | 50(%) |

| performance | Alkali resistance, high temperature resistance, acid resistance |

| Specification | Customized stainless steel mesh |

Features

1.High-efficiency filtration: The wave soldering exhaust filter

adopts high-efficiency filter materials and structures, which can

effectively filter smoke, oxides and other harmful substances

generated during the welding process and purify the air.

2.High temperature resistance: Designed to be made of high temperature resistant materials, it can operate stably in high temperature welding environments and is not easily affected by smoke, dust and heat.

3.Anti-corrosion: It has good anti-corrosion performance and can resist the erosion of corrosive gases and liquids generated during the welding process, extending its service life.

4.Precise filtration: The filter is precisely designed to accurately filter target particles and harmful substances, ensuring the best balance between filtration effect and ventilation performance.

5.Easy to replace and clean: Designed to be easy to replace and clean, it is convenient for maintenance personnel to perform daily maintenance and maintenance, reducing equipment downtime and improving production efficiency.

6.Environmentally friendly and reliable: It complies with environmental protection standards, does not contain harmful substances, will not pollute the environment, and protects the production environment and employee health.

| High-efficiency filtration | The exhaust filter uses high-efficiency filter materials, which can effectively capture smoke, exhaust gas and harmful substances generated during the welding process |

| Good ventilation performance | Reasonable design to maintain good ventilation performance of the equipment, ensure fresh air in the work area, and improve operator comfort |

| Easy to clean and maintain | Designed to be easy to clean and maintain, the filter material can be cleaned or replaced regularly to extend the service life of the filter and maintain filtration efficiency |

| Safe and reliable | Effectively protect operators from harmful gases and smoke, ensuring the safety and hygiene of the production environment |

| Environmental protection and energy saving | Comply with environmental protection requirements, effectively purify exhaust emissions, reduce environmental pollution and save energy |

| Wide applicability | Suitable for wave soldering equipment of various specifications and models to meet the needs of different production scenarios |

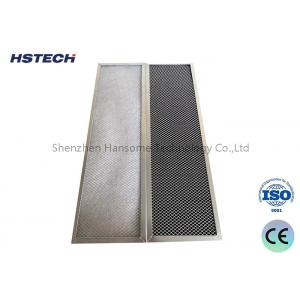

Image display

Physical display