Add to Cart

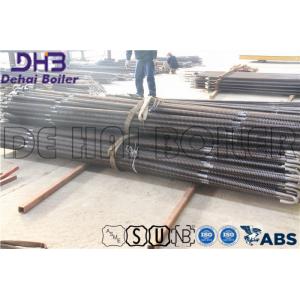

Thermal resistant spiral fin tube industrial Boiler shell and tube heat exchanger

Product Advantage

1. Add the heat exchange area and reduce the number of tubes, also

increase the fume flow section area to reduce the fume speed and

abrasion.

2. H type fin tube can be made to double H type fin tube, high

rigidness to fit long tube row.

3. H type fin economizer arranged in line to make the space into

many small zones, averaged air flow to reduce the abrasion.

4. With straight channel to gain the best ash-blowing effect.

5. The compact structure to reduce the weight and reduce the

manufacturing cost.

Detail

In order to improve the heat exchange efficiency and extend surface heat transfer, H-type finned tubes have been widely used in boilers and waste heat recovery in recent years. H-type finned tubes are derived largely from rectangle finned tubes. Because of their unique groove structure on the fin surface, H-type finned tubes have excellent anti-wear and anti-fouling performance.

Quality Control

1 Impact test and Strength calculation report with applied

materials information.

2 100%NDT(non-destructive inspection) report of steel plate, tube

and electrode.

3 X-ray, γ-ray and liquid penetrant test inspection report (welding

seam): to ensure the quality of the entire boiler.

4 Hydraulic test report: ensure the standard working pressure and

safety.

| Name(unit) | Specification(mm) |

| Bare pipe(OD) | 25-300 |

| Bare pipe(Thickness) | 2-30 |

| Fin (Thickness) | 0.4-3.0 |

| Fin (Height) | 5-35 |

| Fin tube thread pitch | 5-35 |

| Fin tube length | ≤15000 |