Carbon Dioxide Carbonated Drink Production Line Inline Filling Systems

Add to Cart

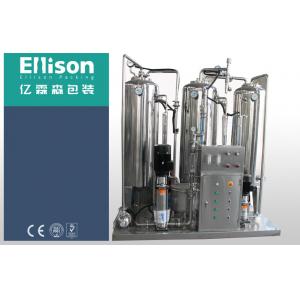

Carbon Dioxide CO2 Carbonated Drink Processing Machine CSD Production Line

Introduction

The CO2 Mixinger is applied to thin beer,aerate for beer and produce sparkling wine. This mixer is advanced in technology, even in mixing, reliable in performance, compact structure, easy in operation. It is suitable for aerated beverage firm of large, middle or small scale.

Application

1. QHS series drink mixer is designed and made for improving the proportion of water, syrup and carbon dioxide.

2. It adopts high-quality water pump and SIEMENS electrical equipment and other parts to form complete automatic control system.

3. It adopts foreign advanced technology static mixer to lighten water layer, extend carbonizing to assure mixing result and deoxying.

4. The advantages are motor coordinating, beautiful appearance, convenient rinsing, high automatic level.

5. It is suitable for mixing all kinds of drink, such as soda water, fruit juice, cola and drinks.

6. It's osculant the drink material parts are adopt the SUS304 stainless steel.

Technical Parameters

| Model | QHS-1500 | QHS-3000 | QHS-4000 | QHS-6000 |

| Production Capability(kg/h) | 1500 | 3000 | 4000 | 6000 |

| Carbon dioxide content | ≥2.5 | ≥2.6 | ≥2.5 | ≥2.5 |

| Inlet temperature of the chilled water(°C) | 3-6 | 3-6 | 3-6 | 3-6 |

| Motor Power(kw) | 1.1 | 2.42 | 3.1 | 4 |

| Overall dimension(L×W×H)(mm) | 1200×1000×1800 | 1500×1000×2000 | 1660×1000×2000 | 1900×1200×2100 |

| Total Weight(kg) | 200 | 350 | 400 | 500 |

Customized service

We can customize the machine according to all the customers(such as

material, power, filling type, bottle size, and so on), at the same

time, our engineers will also give professional advice to help

customers better establish the ideal factory.

Complete solution of CARBONATED DRINK PRODUCTION LINE

1) Water treatment equipment---RO purified equipment, UF purified equipment, Sand filter, Carbon filter, Water softner, Sea Water treatment.

2) Filling Machine---3 in 1 Washing filling capping---for your water, carbonated drink, juice, wine, vinegar, milk, tea and so on.

----150 to 2000ml bottle, 3.5-10L,11- 20L bottle (3-6gallon bottle)

---PET bottle, Glass bottle, PP bottle and Can

----Screw cap, Aluminum cap, Grown cap and three (four) twist caps etc.

3) Labeling Machine---Stick label, Shrink sleeve label, Hot melt Opp labels. Wet glue label

4) Printer , Manual code printer , Inkjet printer , Laser printer

5) Packing Machine----Shrink film, Cartons packing machine

6) Bottle Blowing Machine--- for making plastic bottle

7) Injection Molding Machine---for your cap and perform.

After-sale service

After receiving the final payment, we will provide the bill of

lading on time to ensure that the customer receives the goods as

soon as possible.

When you have completed all the preparations, we will send

engineers to your factory to install the machines and train your

employees until they can operate the machine very well.

We can provide one year warranty with spare parts free, And free

lifetime technical service.

»»» »»» »»» WELCOME TO VISIT US ««« ««« «««

Contact person: Vickie Sun

MOB (whatsapp / wechat): 0086 13584426100

Email: sunpiu2012@gmail.com

Skype: vickiesunqiu