Product Details

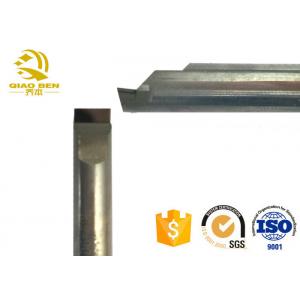

PCD polishing tool car burr precision processing of non - ferrous

me Aluminium work piece Processing mobile phone frame

overview

Scope of application: hardware parts;Auto parts;Surface

treatment;Process products;Carved;Copper batch flower;Mobile phone

metal buttons;Phone case;Digital shell;Metallic highlights;Watch

surface, word nail;Case inside the knife;Nameplate, plate

highlights flower;Car CD lines;Multicolored pattern;Sun

pattern;Highlights of aluminum products;Electrical shell

flower;Electrical panel;Vehicle panel;Computer

peripherals;Transparent computer case;Acrylic polishing;Pressing

force (plexiglass) highlight (polishing) chamfering;The

lens;Windows;Motor commutator precision car etc.Mainly used for all

kinds of metal, gold, silver, copper, aluminum alloy, zinc alloy

and non-metallic materials, acrylic, PVC, PC, plastic and other

materials high-gloss chamfering and straight edge recording light

cutting, cutting surface bright mirror high-gloss effect, long

service life.Customize diamond width, Angle, material and dimension

of tool tip according to requirements.Chamfer cutter general and

commonly used specifications in 45 ° and 75 °, 78 °, the width of

the diamond is 3.0 * 3.0 MM.

Machining features: strong stability, specular high light, smooth

chip, reduce cutting resistance, improve machining efficiency and

tool life.

Tool can be repeated grinding several times: tool raw materials

used industry standard screening, to ensure that the quality of the

tool in the case of wear, without changing the tool, our company

provides grinding service, after our company grinding tool, restore

the past cutting quality, effective savings in processing costs.

Our advantage:

- 1. 10 years experience in carbide roll and cutting tool

manufacturing

- 2. From row material to tool produdtion.

- 3. World top level prodution equipment and rich experience team

ATTACTION:

- 1.Make sure work piece and machine are stable and use a precision

holder.

- 2.Please adjust the speed,feed and cutting depth according to

actual cutting conditions.

- 3.The milling conditions are for an end mill where the tool

overhang length is less than 4*D(mill diameter). When the tool

overhang length is longer, please adjust the speed,feed and cutting

depth.

Company Profile

ShenZhen Joeben Diamond Cutting Tools CO,.Ltd

Joeben is a national high-tech enterprise that independently

develops,produces and sells high precision cutting tools and their

supporting .After several years of efforts and exploration ,it has

been far ahead by its excellent quality and high-quality serivce in

cutting tool industry .Diamond cutting tool,naturral

diamond(ND)cutting tool,Polycrystaline diamond (PCD)cutting

tool,polycrystalline cubic boron nirtide(PCBN)cutting tool,CBN

cutting tool,PCD polishiing cutter,chamfering cutter,milling

cutte,high optical cutter,acrylic diamond polishing cutter and

high-performance metal cutting tool,etc.are our major

products,which have been mainly applied in the processing of

high-end brand mobile phone’s shell,such as apple and Samsung,the

indusrty of taransportation components and.Our company is also

expert in the polishing processing of aluminum

alloy,acrylic,plastic and light guide plate,etc..All of our

products have passde ISO9001 quality system certification.

The company began to design and develop CNC machine tools in

2017and has met its own processing needs.

At present, the company has 80 employees, including 15 engineering

design team, 50 production staff and 10 quality inspection staff.

Our company's vision is to build a world-class quality cutting tool

brand.