Add to Cart

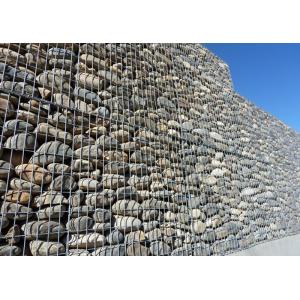

1x1x0.5m 2x1x1m Welded Mesh Gabion Box, Gabion Retaining Wall

Description

Welded Mesh Gabion Box is made of Welded Wire Mesh panels assembled with spirals, locking pins and stiffener. Each gabion panel is composed of rugged high tensile wire coated by a thick, corrosion-resistant layer of zinc.

Welded mesh gabion box is manufactured from cold steel wire with high tensile strength. It is electrically welded together then hot dipped galvanized or PVC coated, ensuring a longer life. There are galvanized welded gabions and PVC welded gabions. Welded Gabion box is designed on the principle of mass earth retaining wall. The strength of the wire mesh helps to stand the forces generated by the retained soil.

1. MOQ:100 sets

2. Type:Weld mesh

3. Wire dia: 2.4-3.5mm

4. Material:galvanized steel wire

5. Surface Treatment: Hot dip galvanized

6. Usage: Used for garden,road,playground,park etc

7. Packaging Details: Packed with plastic film then on the pallets and then in wooden box

8. Mesh size: 50x70mm, 50x100mm, 80x100mm or according to customers’ requirements.

9. Box size: 0.5x0.5x1m, 1x1x1m, 1x1x2m, 1x1x3m, 1x1x4m, 2x1x0.5m, 4x1x0.5m.Custom orders avaliable.

Feature

1. Economic. Just fill the stone into the gabions and seal it.

2. Simple installation. No special technology needed;

3. Weather proof under natural destroys corrosion resistant;

4. No collapse even under big scope of deforming;

5. Sludge in the stones is good for plant growing. Mixed to form a integrity with the natural environment;

6. Good permeation can prevent the damage by hydrostatic;

7. Less transport freight. It can be folded together for transport and further installation.

How to install Welded Gabion Box?

1) Foundation preparation

The foundation on which the gabions are to be placed shall be cut

or filled and graded as required. Surface irregularities, loose

material, vegetation, and all foreign matter shall be removed from

foundation surface area. Extra care should be taken with foundation

preparations in order to ensure a level and smooth surface.

2) Assembly

Rotate the gabion panels into position and join the vertical edges

with fasteners for gabion assembly. Where spiral fasteners are

used, crimp the ends to secure the spirals in place. Where C ring

type alternate fasteners are used for basket assembly, install the

fasteners at a maximum spacing of 150 mm. Use the same fastening

procedures to install interior diaphragms where they are required.

Interior diaphragms will be required where any inside dimension

exceeds 1m for gabion baskets. Diaphragms will be installed to

assure that no open intervals are present that exceeds 1m.

3) Placement

Place the empty gabions on the foundation and interconnect the

adjacent gabions along the top, bottom, and vertical edges using

spirals or C rings.

4) Filling

The gabions shall be carefully filled with rock, ensuring

alignment, avoiding bulges, and providing a compact mass that

minimizes voids.

The last layer of rock shall be uniformly leveled to the top edges

of the gabions. Lids shall be placed over the rock filling using

only approved lid closing tools as necessary. The use of crowbars

or other single point leverage bars for lid closing is prohibited

due to the potential for damage to the baskets. The gabion lid

shall then be secured to the sides, ends, and diaphragms with

spiral binders, approved alternate fasteners, or lacing wire

wrapped with alternating single and double halfhitches in the mesh

openings.

Application

| 1. Control and guide of water or flood | 2. Preventing of rock breaking |

| 3. Rock fall protection | 4. Water and soil protection |

| 5. Bridge protection | 6.Strengthening structure of soil |

| 7. Protection engineering of seaside area | 8. Port project |

| 9. Keep off dust wall | 10.roadway protection |