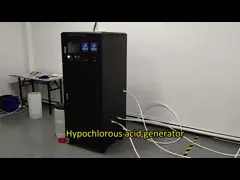

Environment Friendly Easy Operation Sodium Hypochlorite Production System with CE

Add to Cart

Environment Friendly Easy Operation Sodium Hypochlorite Production System with CE

Brief Introduction

Sodium hypochlorite generator is producing sodium hypochlorite by brine electrolysis, and the whole system is a combination of salt dissolving unit, brine proportioning unit, electrolytic unit, rectifier power supply, automatic control systems, storage and dosing unit, etc. The sodium hypochlorite is a strong oxidant, has strong ability to kill algae, bacteria and other contaminants, make indicators of water bacterial colony meet the criteria.

Disinfection method of sodium hypochlorite

Sodium hypochlorite turn into hypochlorous acid by hydrolysis in water, and turn into nascent oxygen [O] in further step, which having ultra strong oxidation to effect the protein of thalli and virus, and terminate pathogenic microorganisms. Besides that, during the reaction of hypochlorous acid, it’s not only having effects on cell wall and viral coat, but due to its small volume and no electrical charge, it’s also permeate into germ or virus generate oxidation reaction with the organic polymer like protein, nucleic acid and enzyme, and thus to kill pathogenic microbes. What’s more, the chlorine ion generated by hypochlorous acid will change the osmotic pressure significantly, cause death of cell by lost of activity.

Principle of sodium hypochlorite generator

Saline solution contains the several kinds of ions such as Na +, H -, when electrolysis, under a certain voltage, as a result of the movement of ions in the electrolyte solution and electrode reaction, the conductive effect occurs, then CL -, OH - such as negative ion to the anode, and positive ions such as Na +, H + to the cathode, and the corresponding electrode discharge occurs, thus carries on the REDOX reaction, the corresponding material production.

Electrode reaction:

anode: 2Cl- - 2e → Cl2;

cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

Na Cl + H2O + DC →NaClO + H2↑

Specification

Brine concentration: 2.5~3.0%;

Salt consumption<3.5Kg/Kg.Cl2;

DC power consumption<4.0KWh/Kg.Cl2;

Available chlorine: 7g/L~9g/L;

Operating mode: full-automatic control, 24 hours continuous work;

Anode coating life:> 5years,can be coated and used repeatedly;

Working temperature: -10 ℃~+50℃;

Electrolyte flow: 125L/hr;

Cooling water flow: recycle system inside the electrolysis cell;

Electrolyte temperature rise range< 5 ℃;

Chlorine production :1 Kg/hr;

Comparison between Geemblue series system and other system

| Technical and economy index | quality A level system | Geemblue system | Comparison |

| Current efficiency | >72% | >90% | 20% up |

| DC consumption | 4.5 kwh/kg Cl2 | 4.0 kwh/kg Cl2 | 11.1% save |

| AC consumption | 6.0 kwh/kg Cl2 | 5.0 kwh/kg Cl2 | 16.6% save |

| Salt consumption | 4 kg/kgCl2 | 3 kg/kgCl2 | 12.5% save |

| Enhancement test of anode life | 20 hour | 100 hour | 5 times higher |