220V 50Hz Water Treatment Equipment Of Brine Electrolysis System For Water Plant

Add to Cart

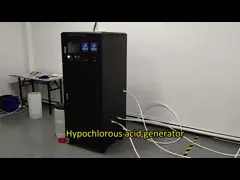

water treatment equipment of brine electrolysis system for water plant

Sodium hypochlorite generator summary:

1.Sodium hypochlorite generation

Sodium hypochlorite generation system is producing sodium hypochlorite through brine electrolysis, and the whole system is a combination of Softening unit, Filtration unit, Salt dissolving unit, Online proportioning unit, electrolytic unit, rectifier power supply, automatic control systems, storage and dosing unit, etc.

2. The Applications of sodium hypochlorite disinfection

Sodium hypochlorite, a strong oxidant with strong bactericidal and bleaching power, have been widely used in drinking water disinfection, food processing, industrial or power system recycling water disinfection, sewage treatment and swimming pool water treatment.

Principle of sodium hypochlorite generator

Salt solution contains the several kinds of ions such as Na+, H+, when electrolysis, under a certain voltage, as a result of the

movement of ions in the electrolyte solution and electrode

reaction, the conductive effect occurs, then Cl-, OH- such as negative ion to the anode, and positive ions such as Na+, H+ to the cathode, and the corresponding electrode discharge occurs,

thus carries on the REDOX reaction, the corresponding material

production. The electrode reaction and solution reactions is

Electrode reaction:

anode: 2Cl- - 2e- → Cl2;

cathode: 2H+ + 2e- → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

NaCl + H2O + DC →NaClO + H2↑

① Influent water passes through a water softener to reduce hardness therefore reducing the scaling of electrodes and lengthening the cleaning time

② Salt is dissolved by softened water into saturated brine in the tank.

③ The saturated brine will be diluted into 2.5%-3%, then pass through the electrolytic cell and finally be electrolyzed into 0.8% solution of sodium hypochlorite.

④ The 0.8% hypochlorite solution flows into a storage tank. Hydrogen, the only byproduct of the process, is safely vented to the atmosphere.

⑤ The residual chlorine detector will monitor residual chlorine and return feedback to the PLC center. According to preset standards, the PLC Center will adjust the speed of the dosing pump.

Comparative advantages of chloridose

| Disinfection system | Source of raw materials | Handling of product | Self-life of product | Operation & maintenance | Cost of consumable |

| Chloride hypochlorite | Only Edible salt | No transportation & storage Easy handling | Produced and dosed on site. No storage. No loss of chlorine | Very Easy | Very Economical |

| Chlorine gas | Dependent on Supplier uneconomical for transport | Transportation and Handling is hazardous | Stable | Difficult | Most Economical |

| Bleaching powder | Dependent on supplier | Handling and storage is inconvenient messy | Highly unstable Rapidly losses Chlorine on storage | Inconvenient Difficult & Messy | Expensive |

| Commercial sodium hypochlorite | Dependent on supplier & Uneconomical for Transport | Handling and storage is inconvenient | Unstable & losses chlorine on storage | Fairly Easy | Most Expensive. |