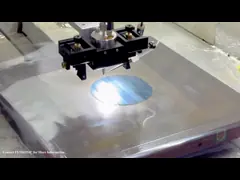

15 Khz Piezoelectric Ceramic Ultrasonic Welding Transducer 3600 Watt 60mm Diameter

Add to Cart

60MM Diameter Pizoelectric Ceramics of Ultrasonic Welding Transducer

Description:

Sound waves are the form of propagation of an object's mechanical vibration state (or energy). The so-called vibration refers to the form of reciprocating motion of the mass point of the substance near its equilibrium position. For example, after the drum surface is knocked, it vibrates up and down. This vibration state propagates through the air medium in all directions, which is sound waves. Ultrasonic means that the vibration frequency is greater than 20,000 Hz, and the number of vibrations per second (frequency) is very high, exceeding the upper limit of the human ear (20000 Hz). People call this inaudible sound wave ultrasonic. Ultrasound and audible sound are essentially identical. They have a common mode of mechanical vibration, which is usually propagated in the elastic medium in the form of longitudinal waves. It is a form of energy propagation, and the difference is that the ultrasonic frequency is high. The wavelength is short, and it has good beamability and directivity along a straight line within a certain distance. At present, the frequency range used for abdominal ultrasound imaging is between 2 and 5 megaHz, and is usually 3 to 3.5 megahertz (vibration per second). 1 time is 1 Hz, 1 mega Hz = 10^6 Hz, that is, 1 million vibrations per hot plate machine, and the frequency of audible waves is between 16-20,000HZ)

Specifications:

| Model | QR-6015-6BD |

| Frequency | 15 khz |

| Output power | 3600 watt |

| Joint bolt | 1/2-20UNF |

| Ceramic disc Diameter | 60mm |

| Qty of ceramic discs | 6pcs |

| Capacitance | 19-22.5nf |

| Amplitude | 10 um |

| Application | Plastic welding machine |

Application:

The electronics industry is the earliest and most popular industry

for ultrasonic cleaning applications.

Cleaning of electronic components: electronic components, such as

housings for semiconductor tubes, housings for ICs, housings for

crystals, housings for relays, and tube holders.

Substrate cleaning of electronic components: The base of electronic

components is made of semiconductor material and encapsulated in a

metal or plastic housing. Before packaging, not only the housing

must be cleaned, but also the substrate must be cleaned, such as IC

chip, resistor, crystal, semiconductor, original film circuit, etc.

PCB board cleaning: Most of the electronics industry in China use

PCB. The flux used for soldering PCB components is divided into

water-soluble, rosin-based and no-clean types. The first two are

used. Ultrasonic cleaning is used (and many are washed with

alcohol). The no-clean type should not be cleaned in principle.

However, most manufacturers in the world still need cleaning even

if they use no-clean flux soldering components. In particular,

high-density PCBs and high-density ICs do not clean or do not use

ultrasonic cleaning, which will lead to the adsorption of dust

between high-density lines and IC outlets. Once the humidity is

high, high-density lines and feet are prone to occur. A short

circuit occurs and a fault occurs, and once the environment is dry,

the short circuit fault disappears by itself, and such a fault is

not easy to find. Therefore, electronic machine factories all over

the world insist on ultrasonic cleaning of PCB boards. In China,

the military electronics complete machine factory has begun to

promote, and has received the double benefits of improving product

reliability and reducing after-sales service costs.

In the production of connectors, connectors, adapters, etc., it

must be cleaned before plating and assembly. Otherwise, dust and

oil adsorbed on these assembled parts will affect its electrical

and insulating properties, especially some complex multi-cores.

This is especially true for connectors.

Cleaning after processing of electronic materials: electronic

materials such as wafers, silicon wafers, and piezoelectric ceramic

sheets are products supplied to component manufacturers. Their

products must be cleaned before leaving the factory, especially for

manufacturers that make their mouths. Difficult, ultrasonic

cleaning is the most effective way.

60MM Diameter Pizoelectric Ceramics of Ultrasonic Welding Transducer