High Frequency Vibration Ultrasonic Assisted Machining , Ultrasonic Spindle High Speed Assisted Machining

Add to Cart

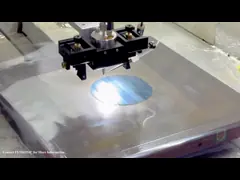

Ultrasonic High Frequency Vibration Spindle High Speed Assisted Machining

Description:

Ultrasonic processing is a sinusoidal electric oscillation signal that an ultrasonic generator converts alternating current into ultrasonic frequency. The transducer converts the electric oscillation signal into ultrasonic frequency mechanical vibration. The horn amplifies the longitudinal vibration of the transducer and transmits it to the tool head. The head is attached with a rotary motion while performing ultrasonic vibration.

Specifications:

| Item No | QR-M20A |

| Power | 100W |

| Generator | Digital generator |

| Frequency | 20KHZ |

| Voltage | 220V |

| Speed | 3000 r / min or less |

| Resonance point amplitude | 10um or more |

| Matching tool | carbide end mill head Φ2-Φ13; disk cutter Φ50 |

Ultrasonic processing features:

(1) Wide processing range

a. It can process hard-working metal, non-metal materials such as hardened steel, stainless steel, titanium and its alloys; especially some non-conductive non-metallic materials such as glass, ceramic, quartz, silicon, agate, gemstone, diamond and various Semiconductors and the like can be processed for conductive hard metal materials such as hardened steel and hard alloy, but have low productivity.

b. Suitable for processing deep deep holes, thin-walled parts, slender rods, low rigidity and complex shapes, and requiring high parts;

c. Suitable for precision machining of precision parts such as high precision and low surface roughness.

(2) Low cutting force and low cutting power consumption Since ultrasonic machining mainly relies on instantaneous local impact, the macro cutting force on the surface of the workpiece is small, and the cutting stress and cutting heat are smaller.

(3) High workpiece processing accuracy and low surface roughness can achieve high machining accuracy (size accuracy of 0.005 to 0.02 mm) and low surface roughness (Ra value of 0.05 to 0.2), no residue on the machined surface Stress, burns, etc., also

Suitable for processing thin-walled, narrow-slit and low-stiffness parts.

(4) It is easy to process various types of holes, cavities and molding surfaces of complex shapes.

(5) Tools can be made into more complex shapes with softer materials.

(6) Ultrasonic processing equipment structure is generally simple, easy to operate and maintain.

Application:

Ultrasonic drilling machine can be used for drilling and engraving some high hardness materials such as crystal, gemstone, agate, jade, glassware, ceramics and enamel, silicon, ferrite and so on. This machine consists of an ultrasonic generator and a processing head (including transducers, horns, etc.). The ultrasonic generator circuit is shown in the drawing. This circuit is simple and consists of three parts: oscillation, push and power amplification.

Ultrasonic High Frequency Vibration Spindle High Speed Assisted Machining